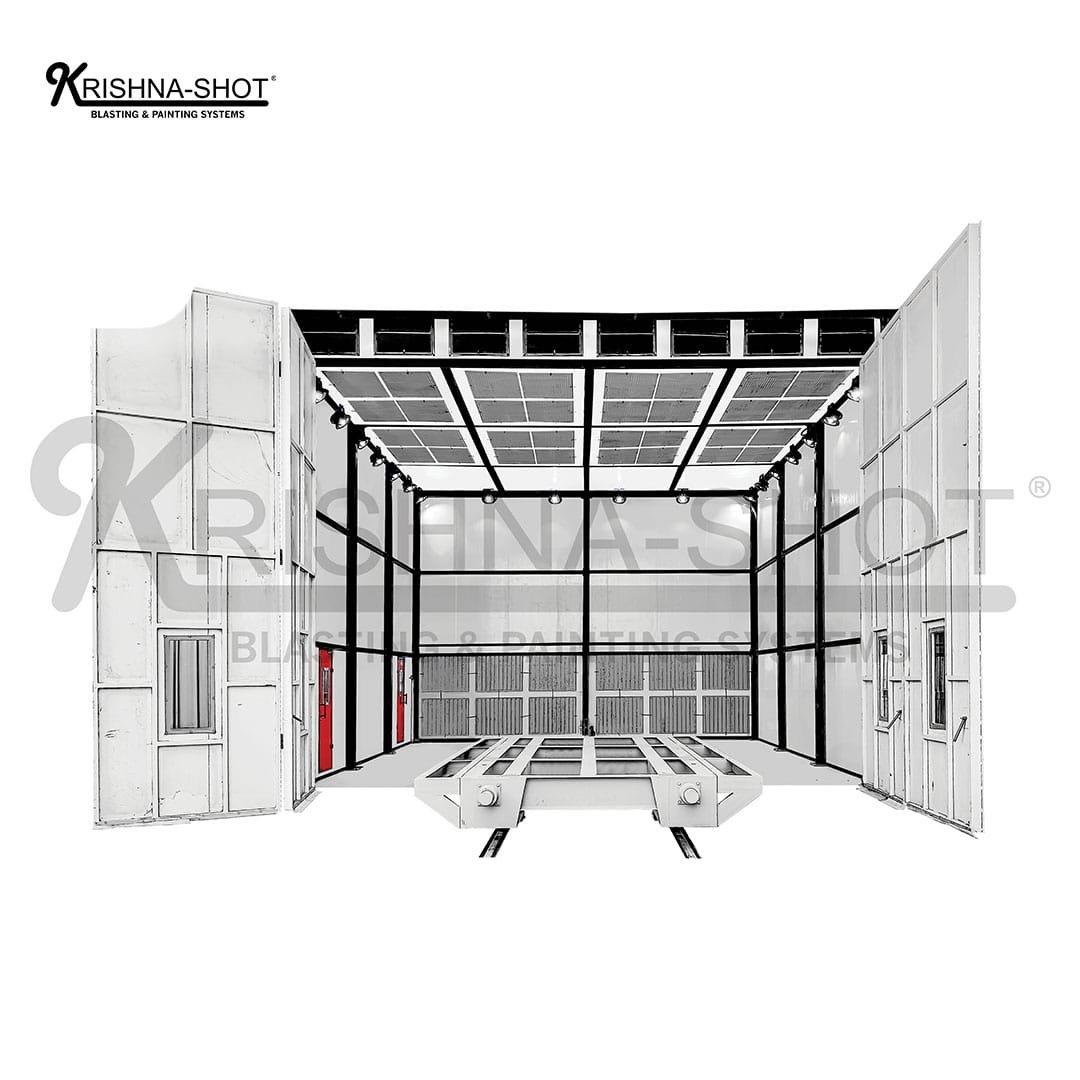

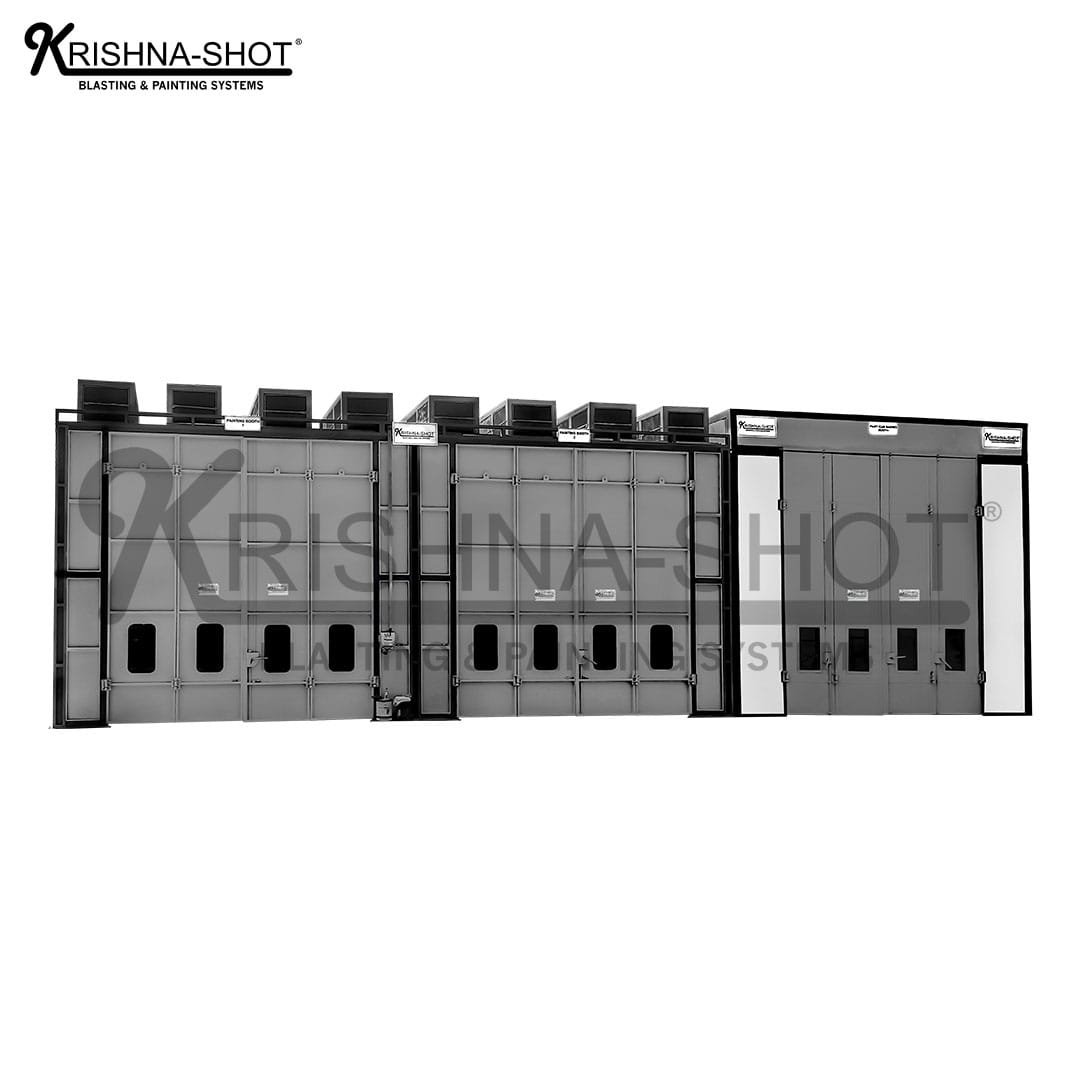

Paint Booth | End Draft System

End Draft Paint Booth System is an innovative solution for high-quality painting and coating processes in industrial settings. Designed for precision, safety, and efficiency, it ensures optimal air circulation and a clean working environment while applying coatings. This system is ideal for automotive, manufacturing, and other industries requiring a controlled environment to ensure smooth, even paint application.

Key Features:

- End Draft Airflow Design: The booth uses an end-draft airflow system, where air flows from the intake at the back of the booth to the exhaust at the front. This design helps maintain a clean and dust-free environment, ensuring better paint adhesion and an even finish.

- High Airflow Efficiency: The system features powerful exhaust and filtration systems that ensure rapid air movement, improving the drying and curing times of the paint while maintaining the cleanliness of the booth.

- Optimal Filtration: The End Draft Paint Booth includes advanced filtration technology to capture overspray and contaminants, preventing them from recirculating into the booth. This ensures the highest quality finish while reducing waste.

- Energy Efficient: Designed to minimize energy consumption, the system uses low-energy fans and filtration units that reduce power costs while maintaining the necessary airflow for efficient paint application.

- Variable Speed Control: The system includes variable speed controls for the fans, allowing the operator to adjust airflow based on specific project requirements. This feature enhances flexibility, enabling optimal performance for different types of coatings and part sizes.

- Safety and Compliance: Equipped with fire suppression and safety features, the End Draft Paint Booth complies with international standards for safety and environmental protection, making it a reliable option for hazardous environments.

- Ergonomic and User-Friendly Design: The paint booth is designed for ease of use, with operator-friendly controls and easy access for maintenance. It ensures a smooth and efficient working experience for your team.

- Customizable Sizes: The End Draft Paint Booth is available in various sizes to accommodate different operational needs. Custom designs are available to meet specific requirements, ensuring it fits seamlessly into your production line.

- Durable Construction: Built from high-quality materials, the booth is designed to withstand heavy usage in harsh industrial environments, ensuring long-term durability and reduced maintenance costs.

Applications:

- Automotive industry (for painting cars, car parts, and components).

- Heavy equipment manufacturing (coating of large machinery and equipment).

- Metalworking industries (for coating metal products).

- Furniture coating (for painting metal and wooden furniture).

Benefits:

- Clean and controlled painting environment for high-quality finishes.

- Reduced overspray and contamination, improving operational efficiency.

- Energy-saving operation that reduces overall costs.

- Enhanced safety features that meet international safety standards.

- Customizable to meet the unique requirements of various industries.