Blast Room | H-Shape Screw Conveyor Recovery System

Manufacturer & Supplier Details

- Brand Name: KRISHNA-SHOT®

- Company Name: Krishna Shot Blasting India Pvt. Ltd.

- Experience: 20+ Years in Surface Finishing Solutions

- Verification: Trustseal Verified (Leading Manufacturer & Supplier)

- Delivery Time: Typically 30 Days

- Address: Plot No. 30, Sarita Vihar Nagar, Near Tanawada, Main Salawas Rd, Jodhpur, Rajasthan 342005

- Specialization: Shot Blasting Machines, Blast Rooms, and Paint Booth Systems

- Customer Support: Dedicated after-sales service and technical support

- Certifications: ISO-certified products

Description

Blast Room with H-Shape Screw Conveyor Recovery System: The Ultimate Solution for Abrasive Blasting and Efficient Media Recycling

Blast Room with H-Shape Screw Conveyor Recovery System is a state-of-the-art industrial system designed to optimize abrasive blasting and surface preparation processes. This advanced system is specifically engineered to handle large parts and components that require cleaning, rust removal, coating, or finishing through abrasive blasting. The H-shape screw conveyor recovery system is a key feature of the blast room, designed to efficiently collect and recycle used abrasive media, reducing material costs and improving operational efficiency.

In this article, we will discuss the features, benefits, and applications of the Blast Room with H-Shape Screw Conveyor Recovery System, and how this innovative system can enhance your industrial blasting operations.

What is a Blast Room with H-Shape Screw Conveyor Recovery System?

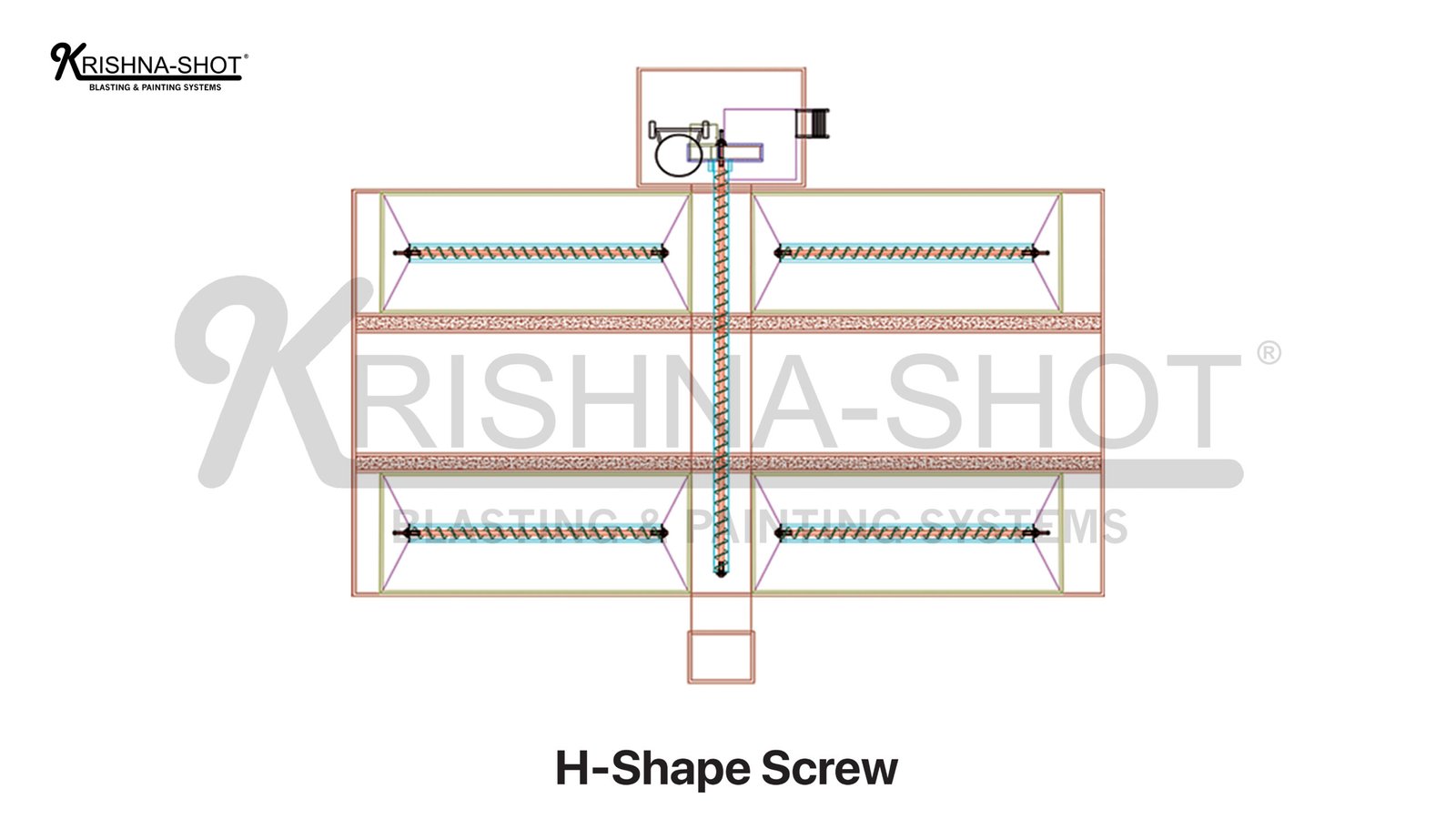

A Blast Room is an enclosed, controlled environment where abrasive blasting is carried out to clean, prepare, or finish workpieces. The H-Shape Screw Conveyor Recovery System is an integral component of this setup that helps collect and recycle the abrasive media used during the blasting process.

The H-shape screw conveyor is a type of screw conveyor with an innovative “H” shape, designed for efficient transportation of abrasive materials from the blast room floor to a storage or recycling system. The unique design of the H-shape screw conveyor maximizes abrasive recovery, minimizes loss, and ensures that media is reused effectively. This results in reduced operational costs and environmental impact.

Key Features of the Blast Room with H-Shape Screw Conveyor Recovery System

- Efficient Abrasive Recovery and Recycling The H-shape screw conveyor efficiently collects used abrasive media from the floor of the blast room and moves it towards a storage area or recycling system. The unique H-shaped design ensures better abrasive flow, preventing blockages and maximizing the recovery of materials. This system helps significantly reduce the amount of abrasive waste and ensures that abrasives are reused for multiple cycles.

- Durable and Robust Construction The H-shape screw conveyor is made from high-quality, wear-resistant materials that can handle the constant abrasive flow within the blast room. The conveyor system is designed to withstand the harsh working conditions and is resistant to the wear and tear caused by abrasive particles. The durability of the system ensures long-term, reliable performance, even in high-volume operations.

- Compact and Space-Efficient Design The H-shape screw conveyor recovery system is compact, making it ideal for blast rooms where space is limited. The system is typically installed below the blast room floor, taking up minimal space while providing efficient abrasive transport. This design ensures that the blast room remains organized, with the conveyor system hidden from the operator’s workspace, helping maintain a clutter-free environment.

- Low Abrasive Loss One of the most significant advantages of the H-shape screw conveyor recovery system is its ability to minimize abrasive loss. The system’s efficient collection and transport mechanism ensure that most of the abrasive media is recovered and recycled, reducing the need for fresh abrasive materials and making the blasting process more cost-effective.

- Improved Productivity By continuously recycling abrasive media, the H-shape screw conveyor minimizes downtime and ensures that the abrasive blasting process is uninterrupted. This allows for continuous operation, improving productivity in high-demand industries that require fast turnaround times and high volumes of workpieces.

- Optimized Dust Collection and Airflow The blast room is equipped with an effective dust collection system that captures airborne particles generated during the blasting process. The controlled airflow and filtration system ensure that dust and debris are contained, protecting the operator from harmful particles and maintaining a safe and clean working environment.

- Minimal Maintenance The H-shape screw conveyor is designed for minimal maintenance. The robust construction and self-cleaning mechanism ensure that abrasive buildup does not clog the system, reducing maintenance needs and downtime. The screw conveyor’s design promotes smooth operation without the need for frequent repairs.

How Does the Blast Room with H-Shape Screw Conveyor Recovery System Work?

- Abrasive Blasting Process The abrasive blasting process begins when high-pressure air or centrifugal force is used to propel abrasive media (such as sand, steel shot, or aluminum oxide) at the workpiece. This removes contaminants like rust, old paint, or coatings, preparing the surface for further processes such as coating, painting, or finishing.

- Collection of Used Abrasives As the abrasive material impacts the workpiece and completes its job, it falls to the floor of the blast room. The H-shape screw conveyor is positioned along the floor to collect the used abrasive. The conveyor collects the abrasive from different parts of the room, ensuring no material is wasted.

- Abrasive Recovery and Recycling Once the used abrasive is collected, the H-shape screw conveyor moves it along the designated path to a central storage area or recycling unit. The conveyor’s efficient design ensures smooth transport and prevents blockages, allowing for continuous abrasive flow without disruption. The abrasive media is then cleaned, filtered, and returned to the blasting system for reuse, minimizing material waste and reducing the cost of purchasing fresh abrasive.

- Dust Collection and Filtration During the blasting process, dust and debris are generated and become airborne. To keep the working environment clean and safe, the blast room is equipped with a dust collection system that removes these particles from the air. The collected dust is then filtered out and disposed of, while the clean air is circulated back into the room.

- Continuous Operation The H-shape screw conveyor continuously feeds the recycled abrasive back into the blasting system, allowing for uninterrupted operation. This results in greater efficiency, as the blasting process does not need to stop to replenish abrasive materials.

Benefits of the Blast Room with H-Shape Screw Conveyor Recovery System

- Cost Savings Through Abrasive Recycling The ability to recycle abrasive media helps to significantly reduce material costs. By recovering and reusing abrasives, this system minimizes the need to purchase fresh media, which is a major expense in abrasive blasting operations. This leads to significant cost savings, especially in high-volume blasting tasks.

- Increased Productivity and Efficiency The H-shape screw conveyor ensures a continuous flow of recycled abrasives, which means the blasting process can operate without interruption. This leads to higher productivity and faster processing times, helping companies meet production targets and deadlines.

- Environmental Benefits The Blast Room with H-Shape Screw Conveyor Recovery System is an environmentally friendly solution. By reducing abrasive waste and reusing materials, the system contributes to sustainability by minimizing the consumption of new abrasives and reducing waste sent to landfills. Additionally, the efficient dust collection system ensures that the air remains clean and free of harmful particles.

- Enhanced Surface Quality The continuous reuse of abrasive media ensures that the blasting process remains consistent, delivering uniform surface preparation. Whether cleaning metal components, removing paint, or preparing surfaces for coating, the system ensures high-quality results that meet industry standards.

- Cleaner, Safer Work Environment The dust collection system integrated into the blast room captures airborne particles, ensuring that the operator is not exposed to harmful dust. This improves the safety and health of workers and ensures compliance with workplace safety regulations.

- Minimal Downtime and Maintenance The H-shape screw conveyor recovery system is designed for minimal maintenance. Its simple, yet robust construction minimizes the risk of malfunctions and reduces the need for regular repairs. This ensures that the system remains operational with minimal downtime, increasing overall efficiency.

Applications of the Blast Room with H-Shape Screw Conveyor Recovery System

- Automotive Industry In the automotive industry, the blast room with H-shape screw conveyor recovery system is used for cleaning parts such as engine components, wheels, and body panels. The system’s ability to recycle abrasives ensures cost-effective and efficient surface preparation.

- Aerospace and Aviation The aerospace industry requires precise cleaning and surface preparation for metal components, aircraft frames, and engine parts. The H-shape screw conveyor ensures that abrasives are reused, providing cost-effective and consistent results.

- Heavy Equipment and Machinery Manufacturing Heavy machinery manufacturers use the blast room for cleaning large components like gears, engine blocks, and frames. The ability to recover and recycle abrasive media makes the blast room a vital part of the surface preparation process.

- Shipbuilding and Marine Industry The marine industry relies on blast rooms to clean large steel components and ship hulls. The H-shape screw conveyor ensures that the blasting process remains efficient while minimizing the use of fresh abrasive material.

Shot Blasting Machine point of view

The Blast Room with H-Shape Screw Conveyor Recovery System is an essential tool for industrial abrasive blasting operations. By efficiently collecting and recycling abrasive media, it reduces waste, lowers operational costs, and enhances productivity. With features like high durability, cost-effective abrasive recovery, and improved surface quality, this system is ideal for industries such as automotive, aerospace, heavy machinery, and marine. Additionally, its compact design, minimal maintenance, and environmental benefits make it a top choice for businesses looking to optimize their blasting operations and improve their bottom line.