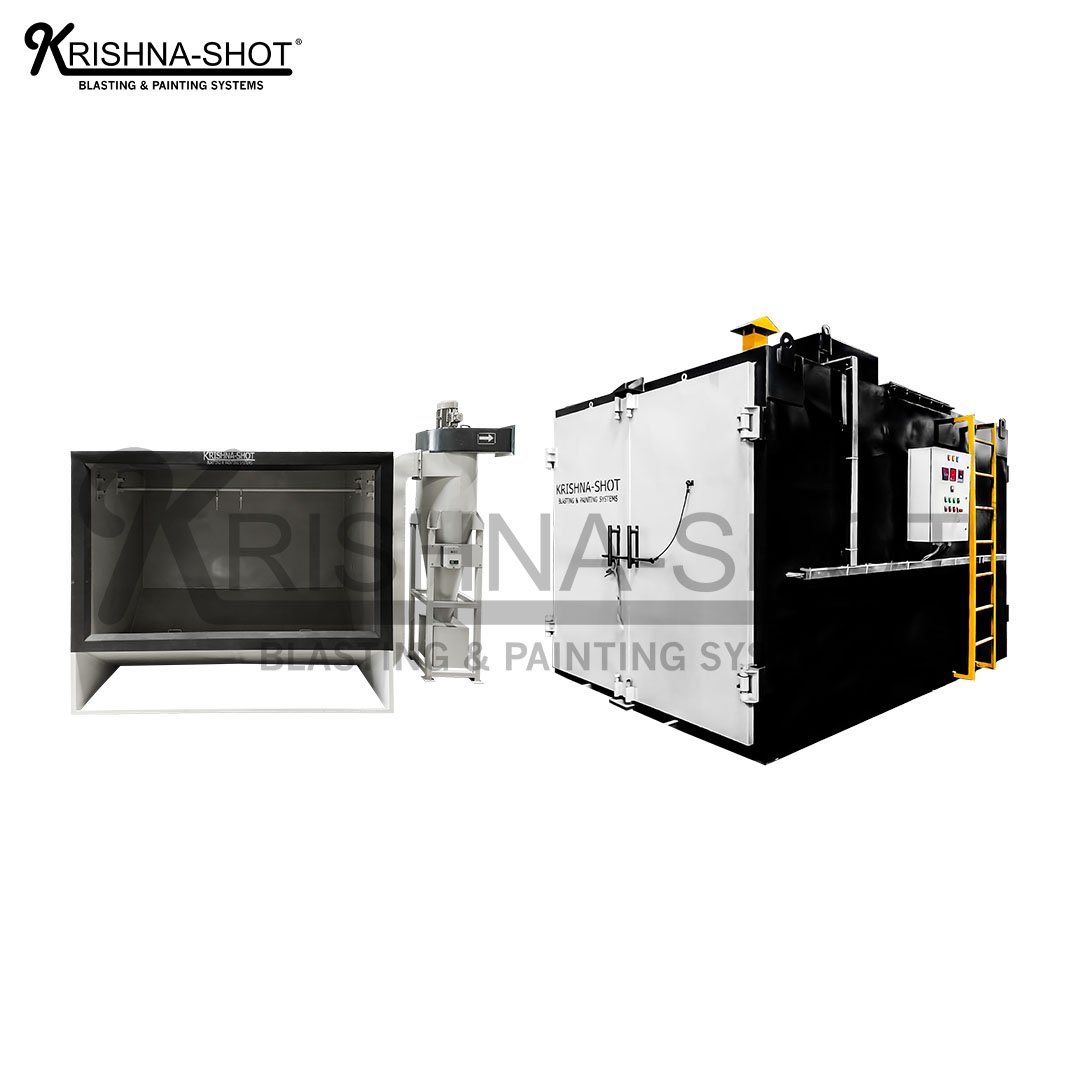

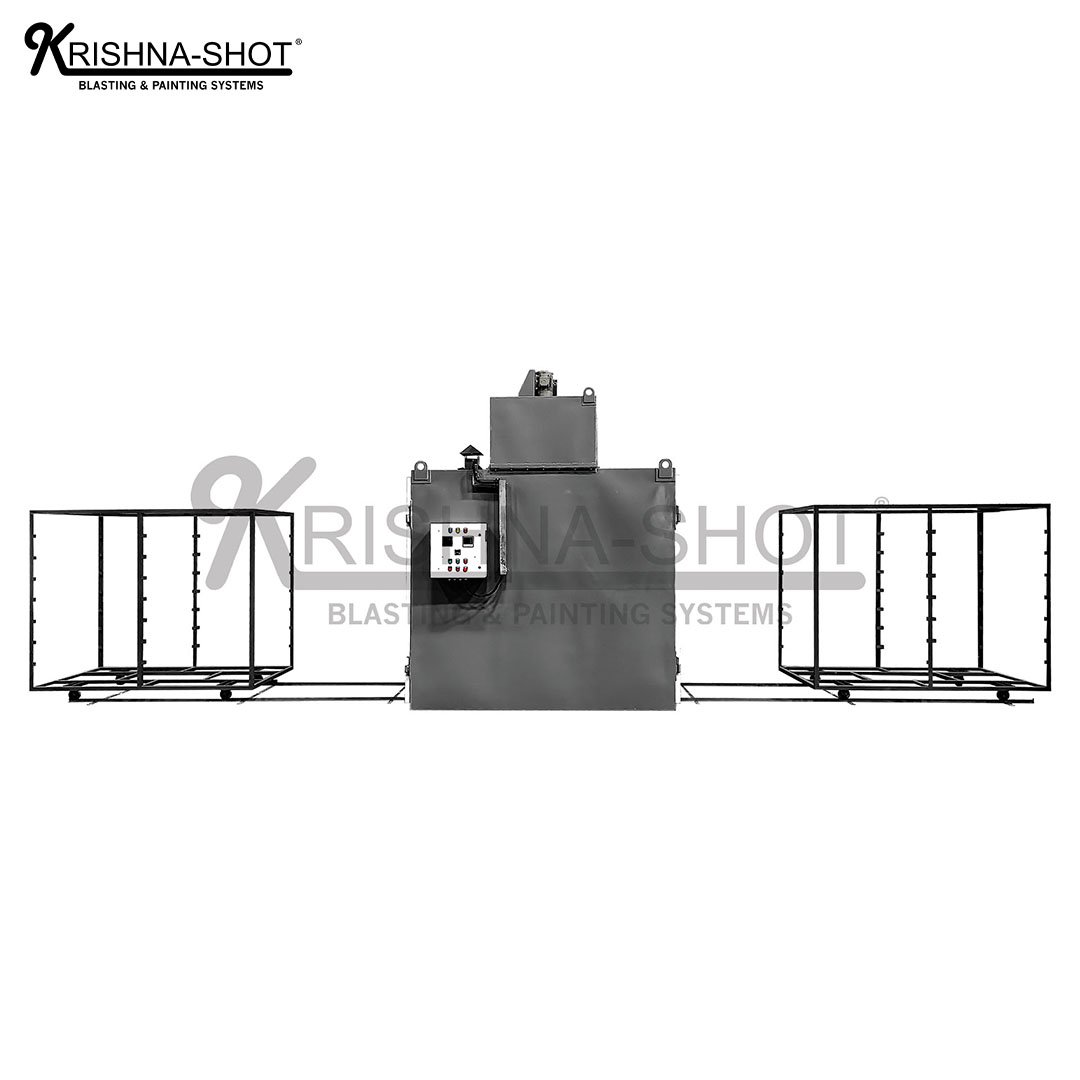

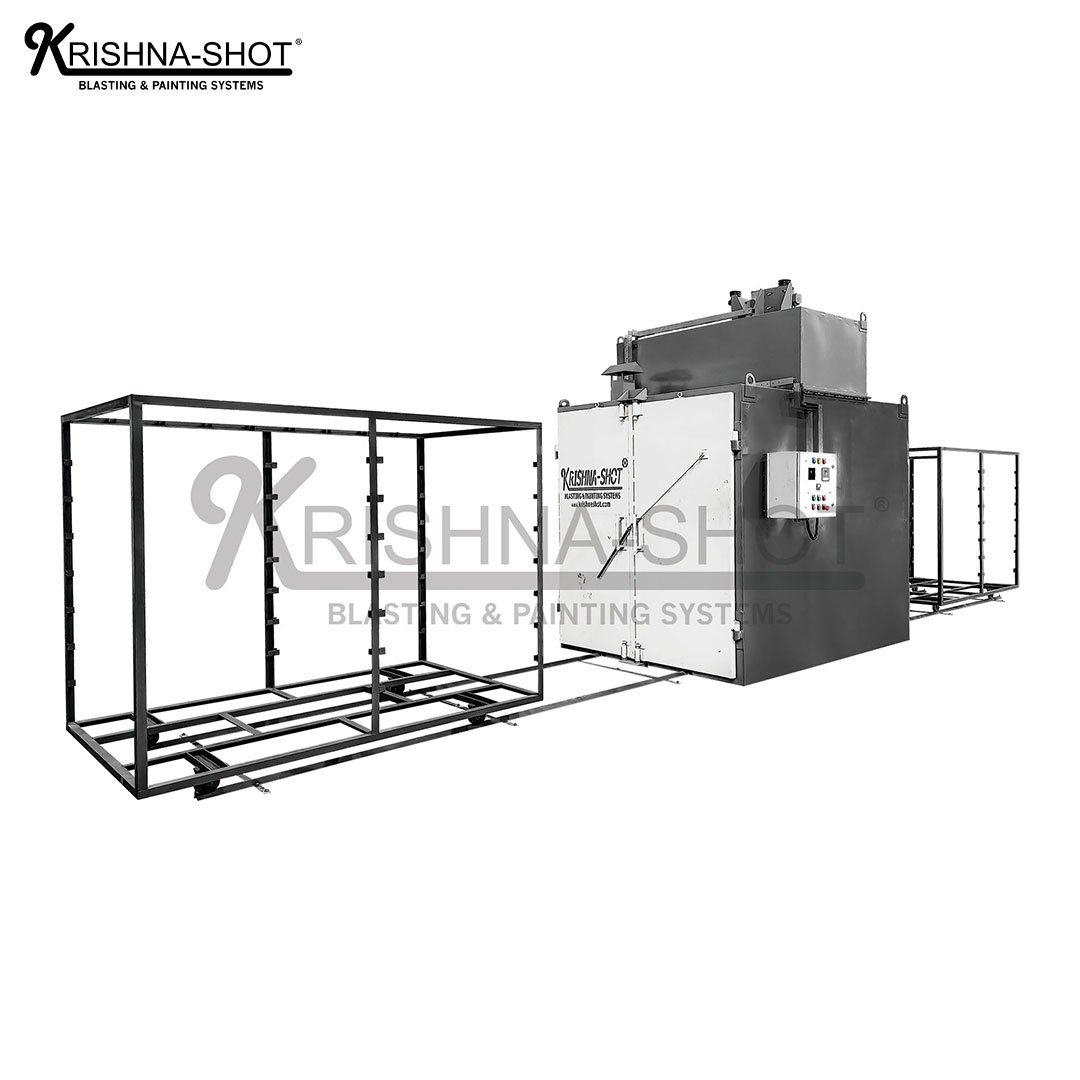

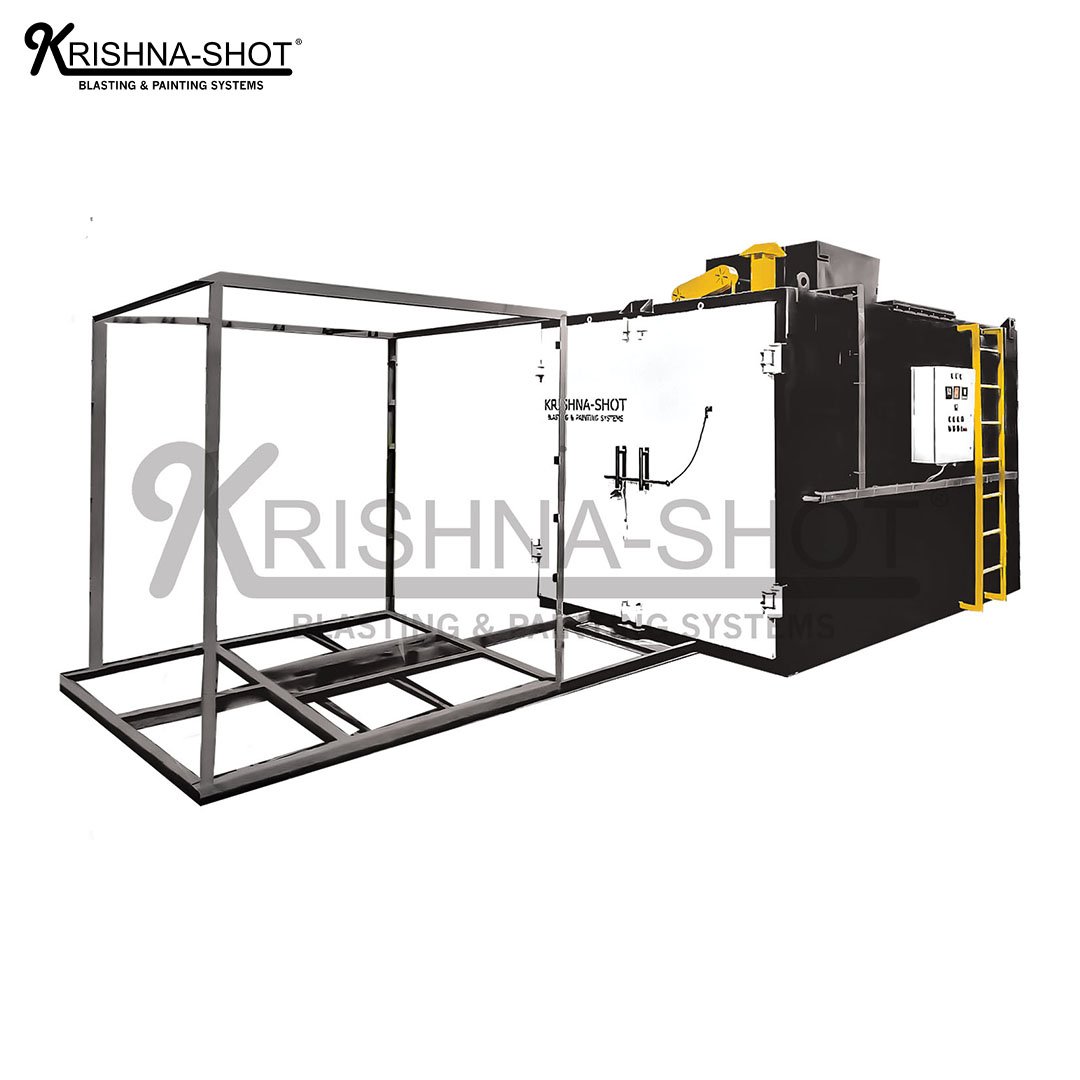

Powder Baking Oven

Manufacturer & Supplier Details

- Brand Name: KRISHNA-SHOT®

- Company Name: Krishna Shot Blasting India Pvt. Ltd.

- Experience: 20+ Years in Surface Finishing Solutions

- Verification: Trustseal Verified (Leading Manufacturer & Supplier)

- Delivery Time: Typically 30 Days

- Address: Plot No. 30, Sarita Vihar Nagar, Near Tanawada, Main Salawas Rd, Jodhpur, Rajasthan 342005

- Specialization: Shot Blasting Machines, Blast Rooms, and Paint Booth Systems

- Customer Support: Dedicated after-sales service and technical support

- Certifications: ISO-certified products

Description

Powder Baking Oven: Essential for High-Quality Powder Coating Curing

Powder Baking Oven is a specialized industrial oven designed to cure powder-coated components, ensuring a durable, smooth, and aesthetically appealing finish. This equipment is a vital part of the powder coating process, which is widely used across industries like automotive, aerospace, appliances, furniture, and industrial machinery. By precisely heating components, the powder baking oven causes the powder coating to melt, flow, and bond to the surface, forming a hard and protective layer.

Key Features of a Powder Baking Oven

- Uniform Heating

Advanced temperature control systems ensure consistent and uniform heating throughout the oven chamber. This prevents uneven curing, which could lead to defects in the coating. - Energy Efficiency

Modern powder baking ovens are designed with energy-saving features such as high-quality insulation and optimized airflow systems, reducing operational costs. - Customizable Temperature Ranges

The oven supports a wide range of temperatures, typically between 180°C and 200°C (356°F to 392°F), making it versatile for curing various types of powder coatings. - Versatile Configurations

Powder baking ovens come in different sizes and configurations, including batch ovens for small-scale production and conveyor ovens for continuous, large-scale operations. - Robust Construction

Built with durable materials, these ovens can withstand high temperatures and heavy-duty industrial usage, ensuring a long service life. - Eco-Friendly Design

Many powder baking ovens are designed to reduce emissions and minimize their environmental impact by using clean energy sources and efficient burners.

How Does a Powder Baking Oven Work?

- Powder Coating Application

Before curing, the component is coated with a dry powder using an electrostatic spray gun. The powder adheres to the surface through electrostatic attraction. - Loading into the Oven

The powder-coated components are placed in the baking oven, either manually for batch ovens or automatically using a conveyor system. - Curing Process

Inside the oven, the components are exposed to precise heat. The powder particles melt, flow, and fuse into a uniform coating. The curing process is carefully controlled to achieve the desired finish and adhesion properties. - Cooling

Once cured, the components are cooled to set the coating. This can be done naturally or with forced cooling systems for faster turnaround times.

Benefits of Using a Powder Baking Oven

- Durable Finish

The oven ensures that the powder coating cures correctly, resulting in a durable, chip-resistant, and corrosion-resistant surface. - High-Quality Results

Precise temperature control and uniform heating eliminate inconsistencies, ensuring a flawless finish. - Increased Efficiency

Conveyor-based powder baking ovens enable continuous operation, boosting productivity for high-volume production. - Cost-Effective Solution

The oven’s energy-efficient design and ability to recycle heat reduce operational expenses, while the durability of powder coatings minimizes maintenance costs. - Environmental Friendliness

Powder coating and baking processes produce minimal waste and emissions compared to traditional painting methods, aligning with eco-friendly manufacturing practices.

Applications of a Powder Baking Oven

- Automotive Industry

Used for curing components such as wheels, bumpers, and body panels, ensuring a sleek and durable finish. - Appliances

Ideal for curing coatings on household appliances like refrigerators, washing machines, and ovens, providing both aesthetic appeal and corrosion resistance. - Furniture Manufacturing

Ensures a long-lasting and attractive finish on metal furniture, including outdoor and office furniture. - Aerospace Components

Provides precision curing for aircraft parts, ensuring durability and adherence to stringent quality standards. - Industrial Equipment

Used to cure coatings on machinery and tools, enhancing durability and resistance to harsh environments.

Types of Powder Baking Ovens

- Batch Ovens

Suitable for small-scale operations or custom jobs, these ovens allow manual loading and curing of individual components. - Conveyor Ovens

Designed for high-volume production, these ovens integrate with automated conveyor systems to enable continuous curing. - Infrared Ovens

Use infrared radiation for rapid heating, reducing curing times and improving energy efficiency. - Gas-Fired or Electric Ovens

Based on energy availability, these ovens provide flexibility in heating methods to suit different operational needs.

Maintenance Tips for Powder Baking Ovens

- Regular Cleaning

Clean the oven chamber and conveyor system to remove accumulated powder particles, ensuring optimal performance. - Inspect Heating Elements

Periodically check the heating elements and burners for wear and replace them as needed. - Calibrate Temperature Controls

Ensure that temperature settings are accurate and consistent to avoid curing defects. - Monitor Airflow Systems

Check fans and ducts for blockages or malfunctions that may impact heat distribution. - Routine Safety Checks

Inspect safety mechanisms, such as emergency shutdown systems, to ensure safe operation.

Why Invest in a Powder Baking Oven?

- Enhanced Productivity

Powder baking ovens streamline the powder coating process, reducing cycle times and improving throughput. - Superior Coating Quality

The controlled curing environment ensures a high-quality finish, enhancing the appearance and durability of coated components. - Scalability

With options for batch and conveyor systems, the ovens cater to both small-scale operations and large-scale manufacturing facilities. - Cost Efficiency

Energy-saving designs and reduced waste make powder baking ovens a cost-effective solution for long-term operations. - Environmental Compliance

Powder baking ovens support eco-friendly manufacturing practices, helping businesses meet environmental regulations.

Shot Blasting Machine Point of view

The Powder Baking Oven is an indispensable tool in modern manufacturing, delivering efficient, high-quality curing for powder-coated components. Its advanced features, energy efficiency, and versatility make it suitable for a wide range of industries, from automotive to furniture manufacturing. Investing in a powder baking oven not only enhances productivity but also ensures a durable and attractive finish, making it a valuable asset for any production line.