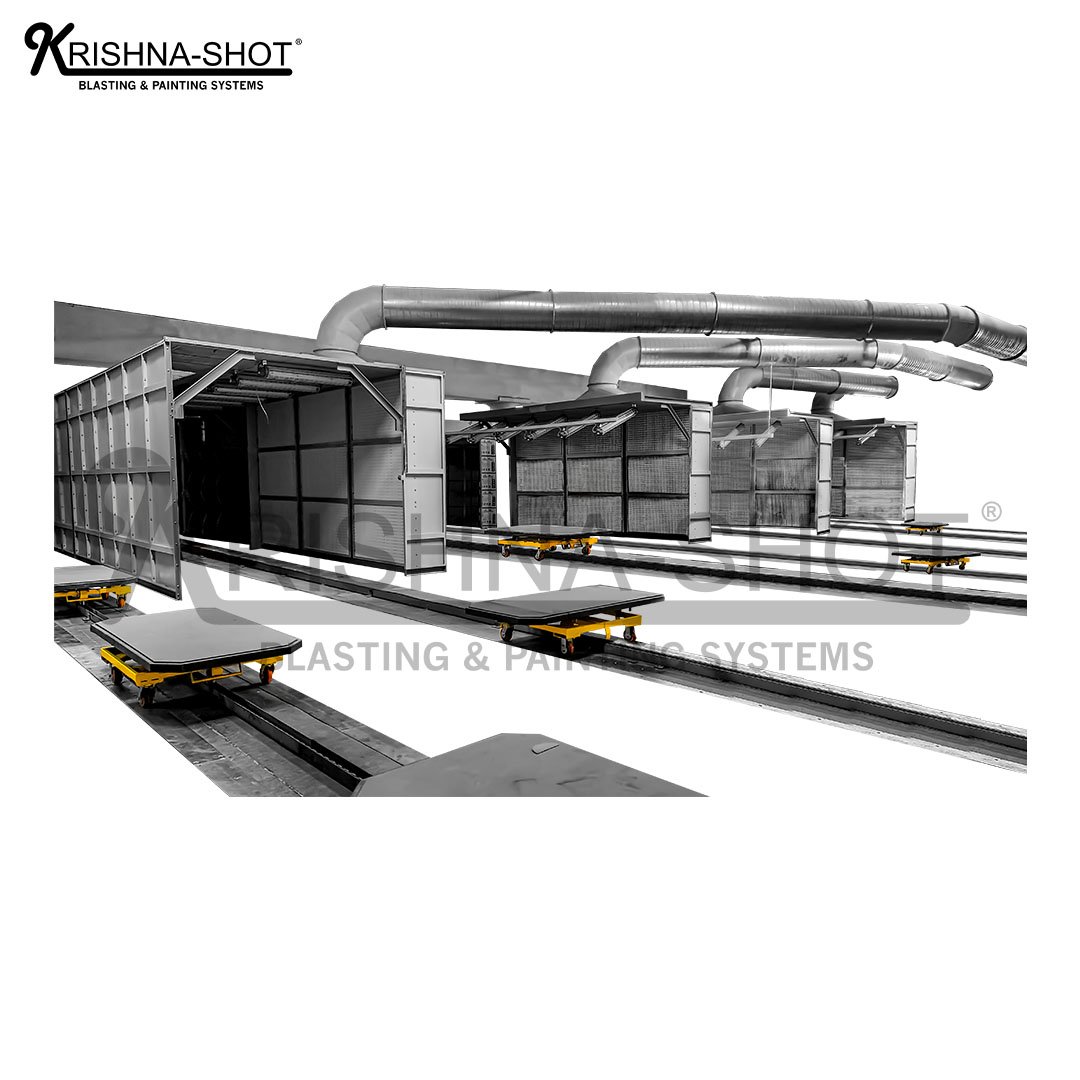

Cart Conveyor Dry Paint Booth Finishing Line

Manufacturer & Supplier Details

- Brand Name: KRISHNA-SHOT®

- Company Name: Krishna Shot Blasting India Pvt. Ltd.

- Experience: 20+ Years in Surface Finishing Solutions

- Verification: Trustseal Verified (Leading Manufacturer & Supplier)

- Delivery Time: Typically 30 Days

- Address: Plot No. 30, Sarita Vihar Nagar, Near Tanawada, Main Salawas Rd, Jodhpur, Rajasthan 342005

- Specialization: Shot Blasting Machines, Blast Rooms, and Paint Booth Systems

- Customer Support: Dedicated after-sales service and technical support

- Certifications: ISO-certified products

Description

Cart Conveyor Finishing Line

A Comprehensive Solution for Efficient Finishing Processes

The Cart Conveyor Finishing Line is a sophisticated, automated system used in various industrial finishing processes, including powder coating, painting, and curing. This system utilizes a cart conveyor mechanism to move components through different stages of the finishing process, offering consistent quality, higher throughput, and operational efficiency. Ideal for industries such as automotive, aerospace, appliances, and heavy machinery, the cart conveyor finishing line streamlines production, reduces labor costs, and ensures uniform, high-quality finishes.

Key Features of a Cart Conveyor Finishing Line

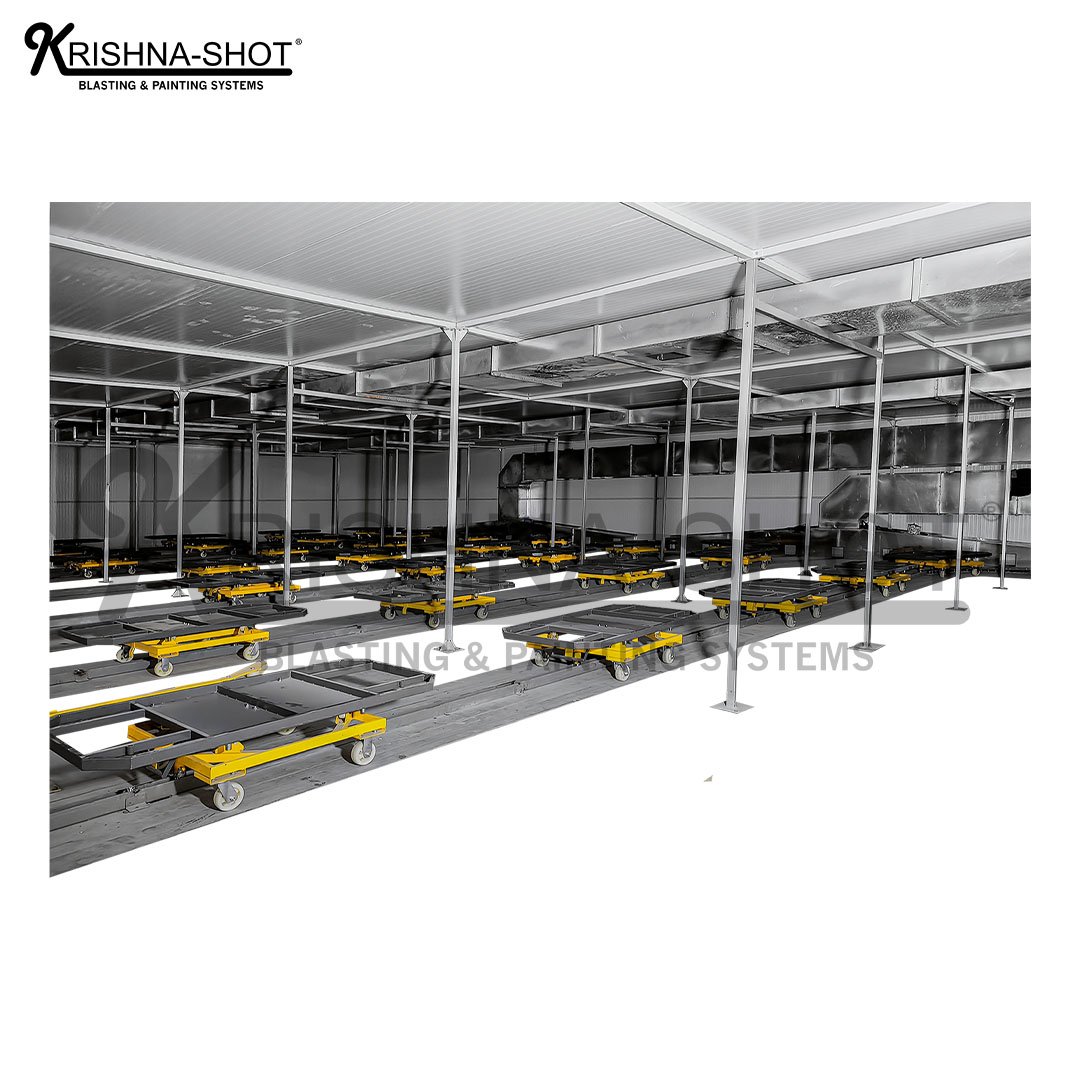

- Automated Cart System The primary feature of the Cart Conveyor Finishing Line is the use of carts that move components from one station to another along a continuous conveyor track. This system minimizes manual handling, reduces the risk of errors, and increases production speed.

- Customizable Configuration These systems are highly customizable to suit the specific needs of different manufacturing environments. From the size of the carts to the length of the conveyor track, the system can be tailored to accommodate a wide range of products and production capacities.

- Multiple Stage Integration The line can integrate multiple stages of the finishing process, including pre-treatment, coating, curing, and cooling. The components are transferred seamlessly between stations, improving operational efficiency and reducing downtime.

- High Durability Built with high-quality materials, the Cart Conveyor Finishing Line is designed to withstand high temperatures and heavy usage. The carts and conveyor belts are constructed to endure the wear and tear of continuous use, ensuring long-lasting performance.

- Energy-Efficient Design The system is designed with energy efficiency in mind, incorporating heat recovery features and energy-saving motors to reduce power consumption while maintaining optimal performance.

- Flexible Loading and Unloading Depending on the design, the system allows for flexible loading and unloading of components. Automated or manual loading options provide versatility, making it easy to handle different product sizes and configurations.

How the Cart Conveyor Finishing Line Works

- Loading The process begins by loading components onto the carts. Depending on the line design, parts can be loaded manually or using an automated loading system. The carts are then moved onto the conveyor system.

- Pre-Treatment The carts with components may first move through pre-treatment stations, where components undergo cleaning, degreasing, or etching. This ensures the surfaces are prepared for optimal coating adhesion.

- Coating Application After pre-treatment, the components are moved to the coating station. Here, they are either spray-painted or powder-coated. The automated conveyor system ensures that each component is coated evenly and consistently, without manual intervention.

- Curing Once the coating is applied, the carts transport the components into a curing oven. The oven is heated to the required temperature for the curing process. The consistent movement of the carts through the oven ensures uniform curing, which is critical for the finish’s durability and appearance.

- Cooling and Unloading After curing, the components are moved to a cooling station where they are allowed to cool down before unloading. Cooling is crucial to set the finish and prevent distortion in the finished product. Once cooled, the parts are unloaded and ready for further processing or packaging.

Benefits of Using a Cart Conveyor Finishing Line

- Increased Efficiency By automating the movement of components through various stages of the finishing process, the Cart Conveyor Finishing Line reduces manual labor and minimizes bottlenecks, which leads to higher production rates.

- Consistent Quality The controlled movement of parts ensures that they receive uniform treatment at every stage. This consistent handling helps maintain high-quality finishes on all products, regardless of their size or shape.

- Flexibility and Scalability The system can be designed to accommodate different component sizes, production volumes, and finishes. Whether you’re handling small parts or large assemblies, the system can be customized to suit your needs.

- Reduced Labor Costs With automated loading, unloading, and movement between stations, the need for manual labor is significantly reduced. This not only saves on labor costs but also minimizes the risk of human error.

- Space Efficiency The cart conveyor system can be designed to fit into existing production lines, often occupying less floor space compared to traditional manual or batch processing setups. This leads to a more organized, space-efficient factory layout.

- Improved Safety Automation reduces the need for workers to manually handle hot or hazardous materials, thus improving safety in the workplace. Additionally, the enclosed systems minimize the exposure of employees to chemicals or harmful fumes.

- Customization for Specific Applications The system can be adapted for various industries such as automotive manufacturing, appliance finishing, and metal coating. Features like adjustable conveyor speeds, multi-stage curing systems, and custom loading/unloading solutions can be integrated based on specific production requirements.

Applications of the Cart Conveyor Finishing Line

- Automotive Industry The Cart Conveyor Finishing Line is widely used in the automotive industry for coating vehicle parts, including bumpers, body panels, and wheels. The system ensures a consistent and high-quality finish for each component, regardless of size.

- Aerospace Manufacturing Aerospace parts often require special coatings for durability and protection. The cart conveyor finishing line can handle large, complex parts while maintaining the required precision and consistency in the coating process.

- Appliance Industry Household appliances, such as refrigerators, ovens, and washing machines, are often powder-coated for both aesthetic and functional purposes. The cart conveyor system allows manufacturers to efficiently coat and cure large batches of appliance parts.

- Furniture Manufacturing Metal furniture, both indoor and outdoor, benefits from powder coating finishes that provide a durable, long-lasting surface. The cart conveyor finishing line efficiently handles the coating and curing of large metal parts like furniture frames.

- Industrial Equipment Industrial machinery and equipment often require robust coatings to protect against corrosion and wear. The cart conveyor system offers a streamlined way to coat and cure these heavy-duty parts, ensuring a high-quality finish.

Maintenance and Care for a Cart Conveyor Finishing Line

- Regular Inspection Periodic inspections of the conveyor system, carts, and oven components ensure that everything is functioning properly. Early detection of wear and tear can prevent downtime and costly repairs.

- Cleaning Routine cleaning of the system, especially the conveyor tracks and carts, is essential to maintain optimal performance. Dust, debris, and coating residues should be removed regularly.

- Lubrication Ensure that all moving parts, such as conveyor belts, rollers, and wheels, are properly lubricated to prevent wear and reduce friction.

- Monitor Temperature Control Regularly calibrate the oven temperature control system to ensure that the curing process occurs at the correct temperature, which is vital for achieving the desired finish quality.

- Check for System Blockages Ensure that there are no blockages in the system that could slow down or halt the production line. Routine checks of airflow and exhaust systems are also essential to prevent overheating.

Shot Blasting Machine Point of View

Cart Conveyor Finishing Line is an indispensable tool for modern manufacturing, offering increased efficiency, consistent quality, and enhanced productivity. By automating the movement of parts through various stages of the finishing process, manufacturers can reduce labor costs, improve coating quality, and ensure that products meet high standards for durability and appearance. Whether you’re working in automotive, aerospace, appliances, or industrial equipment, the cart conveyor finishing line provides a highly customizable, scalable solution to streamline your production process and meet the demands of high-volume manufacturing.