Blasting Media

Manufacturer & Supplier Details

- Brand Name: KRISHNA-SHOT®

- Company Name: Krishna Shot Blasting India Pvt. Ltd.

- Experience: 20+ Years in Surface Finishing Solutions

- Verification: Trustseal Verified (Leading Manufacturer & Supplier)

- Delivery Time: Typically 7+ Days

- Address: Plot No. 30, Sarita Vihar Nagar, Near Tanawada, Main Salawas Rd, Jodhpur, Rajasthan 342005

- Specialization: Shot Blasting Machines, Blast Rooms, and Paint Booth Systems

- Customer Support: Dedicated after-sales service and technical support

- Certifications: ISO-certified products (if applicable)

Description

Blasting Media

Your Key to Superior Surface Preparation and Finishing

Blasting media plays a critical role in the abrasive blasting process, used across industries like metalworking, automotive, aerospace, and construction. It helps in cleaning, smoothing, or etching surfaces by propelling various materials at high speeds. Choosing the right blasting media is essential for achieving a precise surface finish, improving efficiency, and ensuring the quality of the final product.

What is Blasting Media?

Blasting media, also known as abrasive materials, is the substance used in abrasive blasting machines to clean, smooth, or prepare surfaces. It’s made from durable, hard materials capable of withstanding high-speed impacts. The media is shot at a surface through a nozzle to remove contaminants, rust, old coatings, or to smoothen the surface for further treatment. Depending on the surface and desired finish, the type of blasting media can vary, affecting the speed, quality of the finish, and equipment wear.

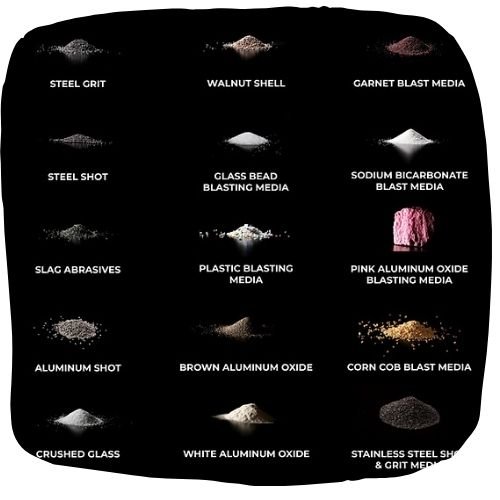

Types of Blasting Media

There are various types of blasting media, each designed for specific applications:

- Silica Sand

- Use: Surface cleaning and rust removal on metals and concrete

- Advantages: Readily available and inexpensive

- Limitations: Health risks due to hazardous silica dust

- Glass Beads

- Use: Polishing and cleaning metals, plastics, and ceramics

- Advantages: Non-toxic, smooth matte finish

- Limitations: Not suitable for heavy-duty cleaning

- Steel Shot & Steel Grit

- Use: Shot blasting for heavy-duty rust and paint removal

- Advantages: Durable and highly effective for cleaning large metal parts

- Limitations: Abrasive on softer surfaces

- Aluminum Oxide

- Use: Cleaning and polishing tough materials

- Advantages: Exceptional cutting power and long lifespan

- Limitations: Hard and aggressive, may damage delicate surfaces

- Walnut Shells

- Use: Gentle cleaning of soft metals and automotive parts

- Advantages: Environmentally friendly, non-toxic

- Limitations: Less effective for heavy-duty tasks

- Copper Slag

- Use: Heavy-duty blasting for rust and scale removal

- Advantages: Aggressive, cost-effective, and recyclable

- Limitations: Sharp edges may damage softer materials

- Baking Soda

- Use: Delicate cleaning of sensitive materials

- Advantages: Environmentally safe and gentle

- Limitations: Less effective for tough cleaning jobs

- Plastic Media

- Use: Soft cleaning tasks like paint stripping

- Advantages: Ideal for plastics, aluminum, and soft metals

- Limitations: Not suitable for aggressive cleaning

How to Choose the Right Blasting Media

Selecting the correct blasting media is essential for achieving the desired results. Consider the following factors:

- Surface Material: The harder the material, the more aggressive the media required.

- Cleaning Objective: Different media are designed for various tasks like stripping, polishing, or roughening surfaces.

- Health & Environmental Impact: Choose media that minimizes dust and health risks.

- Finish Quality: The media choice influences whether you get a smooth, matte, or textured finish.

- Reusability & Cost: Consider media that can be recycled, like steel shot, for cost efficiency.

Applications of Blasting Media

Blasting media is used in multiple industries, including:

- Aerospace: Cleaning aircraft parts for coating or inspection

- Automotive: Prepping car parts before painting

- Construction: Cleaning and finishing concrete or stone surfaces

- Metalworking: Cleaning, deburring, and polishing metal components

- Shipbuilding: Removing rust, paint, and marine growth from ships

Benefits of Blasting Media

- Efficient Surface Cleaning: Quickly removes rust, contaminants, and old coatings, preparing surfaces for finishing.

- Surface Profiling: Certain media roughen surfaces for better adhesion of coatings or paint.

- Improved Adhesion: Prepares surfaces for stronger, longer-lasting finishes.

- Enhanced Productivity: Speeds up cleaning processes, saving both time and labor.

Why Choose Us for Your Blasting Media?

At Shot Blasting Machine in, we offer the best quality blasting media for all your surface preparation and finishing needs. With a wide range of materials suited to different tasks and industries, you can trust us to provide the right solution at the right price.

Click on the “Check Price” button to see our competitive prices and start improving your surface preparation process today!