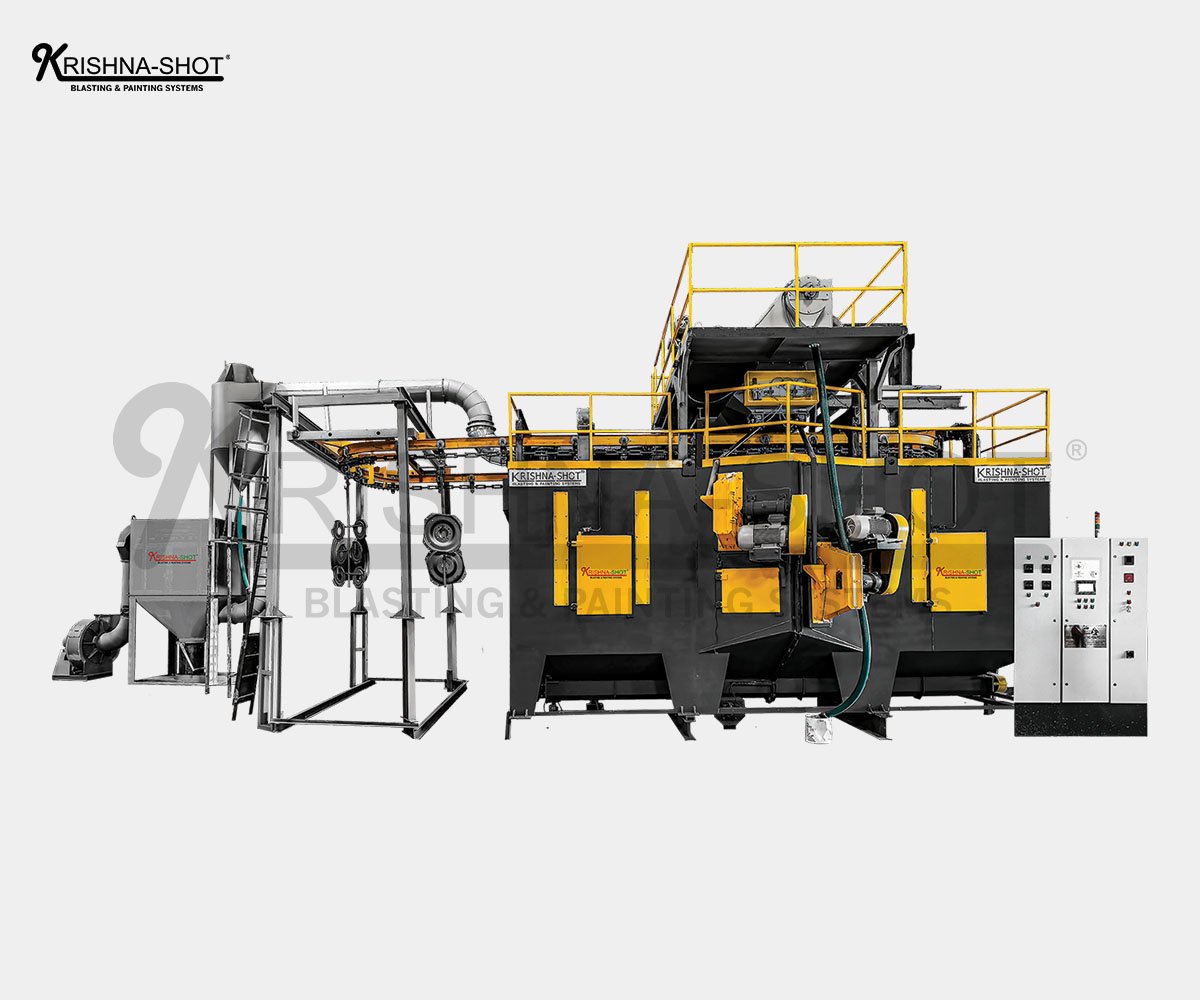

Continuous Conveyor Shot Blasting Machine | Close Loop

Manufacturer & Supplier Details

- Brand Name: KRISHNA-SHOT®

- Company Name: Krishna Shot Blasting India Pvt. Ltd.

- Experience: 20+ Years in Surface Finishing Solutions

- Verification: Trustseal Verified (Leading Manufacturer & Supplier)

- Delivery Time: Typically 30 Days

- Address: Plot No. 30, Sarita Vihar Nagar, Near Tanawada, Main Salawas Rd, Jodhpur, Rajasthan 342005

- Specialization: Shot Blasting Machines, Blast Rooms, and Paint Booth Systems

- Customer Support: Dedicated after-sales service and technical support

- Certifications: ISO-certified products

Description

Close Loop Continuous Conveyor Shot Blasting Machine is a specialized type of shot blasting equipment designed for continuous, high-efficiency surface cleaning, deburring, and finishing. It uses a closed-loop conveyor system to transport parts through the blasting chamber, ensuring consistent quality and high throughput. The machine is commonly used in industries like automotive, aerospace, foundries, and metal processing.

Key Features of a Close Loop Continuous Conveyor Shot Blasting Machine:

- Continuous Conveyor System:

- The machine employs a closed-loop conveyor, which continuously moves workpieces through the blasting area.

- The conveyor can be a belt, roller, or chain type, depending on the size and shape of the parts.

- The continuous movement of parts through the system ensures minimal downtime, leading to high productivity.

- Shot Blasting Process:

- The shot blasting process uses abrasive media, typically steel shot, grit, or other materials, to clean or finish the surfaces of workpieces.

- The abrasive media is accelerated by centrifugal blast wheels or turbines and directed at the workpieces to remove contaminants like rust, scale, or old coatings.

- Closed Loop Design:

- The closed-loop conveyor is fully enclosed, ensuring that the blasting process is contained, which minimizes the escape of abrasive media and debris.

- This design helps maintain a clean work environment and prevents contamination of the workpieces.

- Advantages:

- High Throughput: The continuous conveyor allows for a steady stream of parts to be processed, reducing idle times and increasing production efficiency.

- Consistent Surface Finishing: As parts pass through the blasting chamber multiple times, it ensures uniform cleaning or surface finishing.

- Recyclable Abrasive Media: The system often includes an abrasive recovery system, allowing for the recycling of the abrasive media, which reduces operational costs.

- Compact & Efficient Design: The closed-loop conveyor system allows for efficient use of space in factories and manufacturing facilities.

- Applications:

- Automotive Industry: Cleaning and finishing of cast and machined parts like engine blocks, suspension components, and transmission housings.

- Aerospace: Surface treatment of turbine blades, landing gear parts, and other critical components to ensure optimal performance and durability.

- Metal Foundries: Cleaning and preparing castings before further machining or coating.

- Steel and Metal Manufacturing: Surface preparation for metal parts, including the removal of scales, rust, and coatings.

- Components:

- Blast Wheels or Turbines: These components are responsible for propelling the abrasive media at high velocity toward the workpieces.

- Abrasive Recovery System: Collects and recycles abrasive media for reuse, which minimizes waste and reduces costs.

- Dust Collection System: Captures airborne dust and particles to maintain a clean and safe working environment.

- Automation and Control:

- Modern Close Loop Continuous Conveyor Shot Blasting Machines are typically automated and equipped with control panels for easy adjustment of blast intensity, conveyor speed, and media flow.

- Sensors and monitoring systems ensure precise control over the blasting process for consistent results.

Types of Close Loop Conveyor Shot Blasting Machines:

- Roller Conveyor Type: Ideal for large, heavy, or flat workpieces that need to be cleaned or finished uniformly.

- Hanger Type: Suitable for complex or delicate parts that are suspended from hooks or hangers and moved through the blasting chamber.

- Bucket Conveyor Type: Used for smaller or medium-sized workpieces that are transported in containers or buckets.

Applications:

- Automotive Manufacturing: For parts such as engine components, body frames, and other automotive parts requiring cleaning and finishing.

- Foundries: For the cleaning of castings before coating or additional processing.

- Aerospace and Aviation: For precise cleaning and finishing of parts like turbine blades and aircraft components.

- Metal Fabrication: To remove rust, scale, and contaminants from metal products before coating or further machining.

Benefits:

- Improved Productivity: Continuous operation with minimal downtime leads to faster production cycles and higher throughput.

- Uniform Results: The continuous blasting process ensures all parts are treated consistently, leading to high-quality finishes.

- Environmentally Friendly: Closed-loop systems contain and recycle abrasive materials, reducing waste and operating costs.