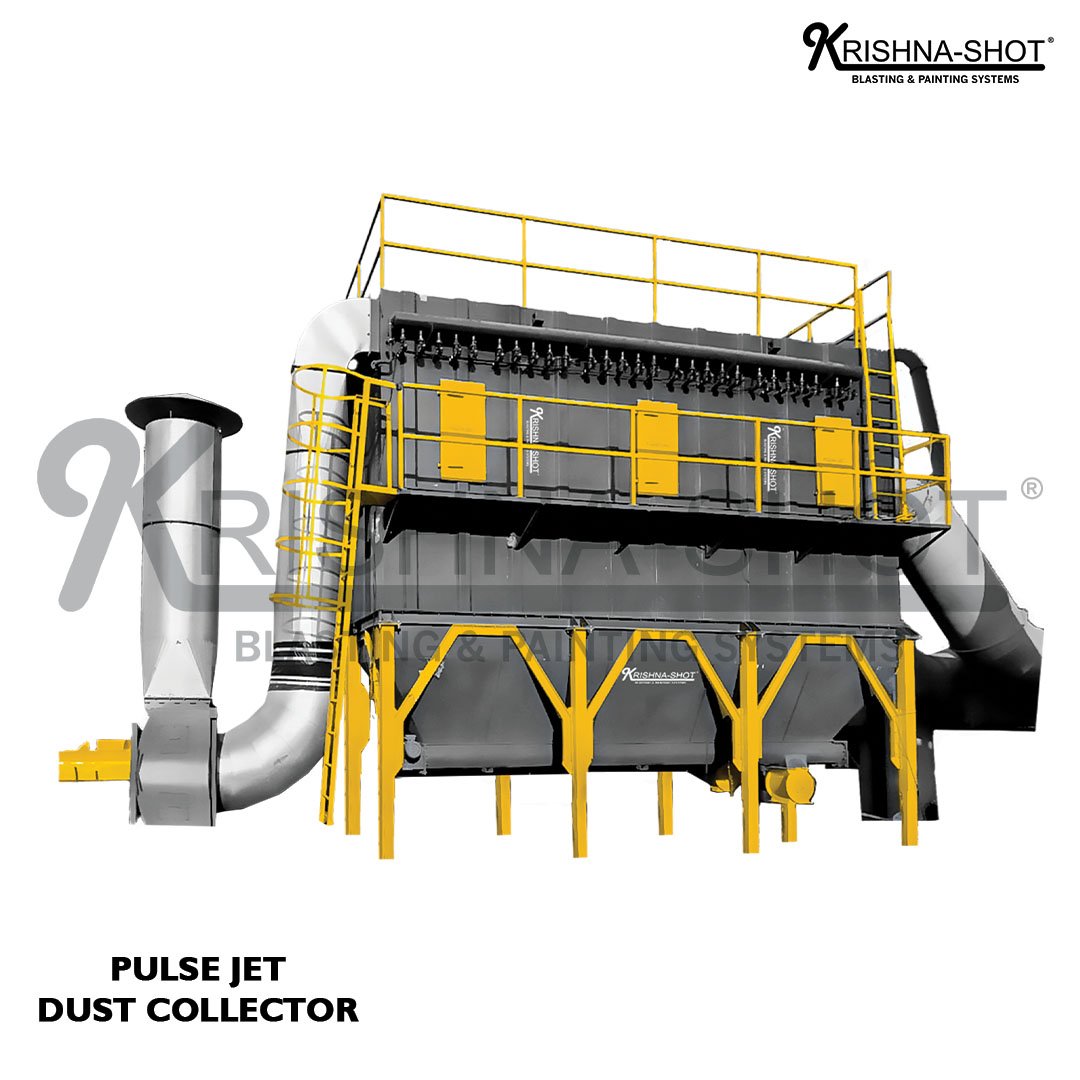

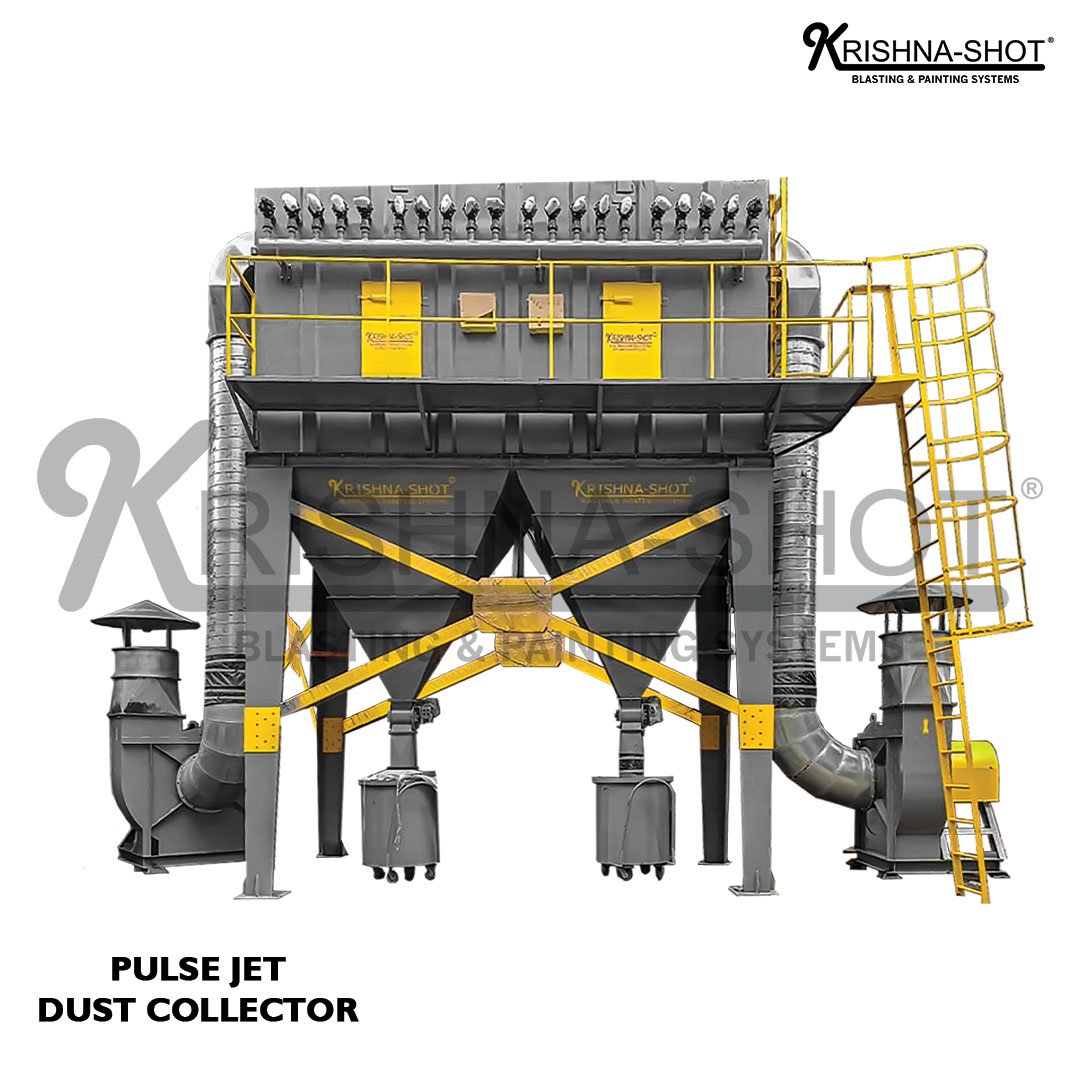

Dust Collector

Manufacturer & Supplier Details

- Brand Name: KRISHNA-SHOT®

- Company Name: Krishna Shot Blasting India Pvt. Ltd.

- Experience: 20+ Years in Surface Finishing Solutions

- Verification: Trustseal Verified (Leading Manufacturer & Supplier)

- Delivery Time: Typically 30 Days

- Address: Plot No. 30, Sarita Vihar Nagar, Near Tanawada, Main Salawas Rd, Jodhpur, Rajasthan 342005

- Specialization: Shot Blasting Machines, Blast Rooms, and Paint Booth Systems

- Customer Support: Dedicated after-sales service and technical support

- Certifications: ISO-certified products

Description

Dust Collector

Essential for Clean and Safe Workplaces

industrial dust collector is a crucial piece of equipment used across various industries to manage and control dust emissions that occur during manufacturing, processing, and handling operations. Dust can be harmful to both the workers’ health and the environment, especially in industries like woodworking, metalworking, pharmaceutical manufacturing, and food processing. An industrial dust collector ensures that these fine particles are efficiently captured and removed from the air, creating a safer, healthier, and cleaner environment.

What is an Industrial Dust Collector?

An industrial dust collector is a system designed to remove dust particles from the air in manufacturing facilities. These dust collectors are designed to capture dust generated from industrial processes like grinding, sanding, cutting, welding, and more. Industrial dust collectors are typically connected to machines or processes that produce dust, where they work to draw in the dust-laden air through a network of ducts and pipes, filter the dust particles, and release clean air back into the environment.

Industrial dust collectors vary in size, design, and application, depending on the type of dust produced, the volume of dust, and the specific needs of the facility. The goal is to ensure efficient dust extraction, improve air quality, and maintain a safe and healthy working environment.

Key Features of an Industrial Dust Collector

- High-Efficiency Filtration

- Industrial dust collectors are equipped with high-performance filters, such as baghouse filters, cartridge filters, or HEPA filters, to capture fine dust particles. These filters trap dust and prevent it from being released back into the air, ensuring cleaner indoor air quality.

- Powerful Airflow Systems

- The system uses large fans or blowers to create the necessary suction to draw dust-laden air through the collection system. These powerful airflow systems are essential for ensuring dust is effectively captured from multiple sources and transported to the dust collection unit.

- Modular Design

- Many industrial dust collectors feature modular designs, allowing them to be customized to meet the specific needs of a facility. These systems can be expanded or reconfigured based on changing operational requirements or an increase in dust output.

- Automatic Cleaning Mechanism

- Many modern dust collectors come with automatic cleaning systems that use reverse air, vibration, or pulse jet technology to clean the filters regularly. This ensures consistent performance and reduces the need for manual intervention.

- Dust Storage and Disposal

- Collected dust is stored in bins or hoppers that are integrated into the dust collector system. Some systems have mechanisms for automated disposal or recycling of the dust, ensuring that it can be easily removed from the system without manual handling.

- Durable Construction

- Industrial dust collectors are built to withstand heavy use and harsh environments. They are constructed from robust materials such as steel or stainless steel to ensure long-lasting durability and resistance to wear and tear from abrasive dust.

- Energy Efficiency

- Many dust collectors are designed to be energy-efficient, utilizing low-energy fans, efficient motors, and optimized airflow designs. This reduces operational costs and ensures sustainable energy consumption over the long term.

Benefits of Using an Industrial Dust Collector

- Improved Worker Health and Safety

- Exposure to airborne dust can lead to respiratory issues, allergies, and even more serious conditions like lung diseases. An industrial dust collector helps remove harmful dust particles from the air, significantly reducing the risk of workers inhaling dangerous substances.

- Enhanced Compliance with Regulations

- Many countries have strict environmental and occupational health and safety regulations that require industries to control dust emissions. An industrial dust collector helps businesses comply with these regulations by ensuring that dust is effectively managed and removed from the workplace.

- Improved Product Quality

- In industries like pharmaceutical manufacturing, food processing, and electronics, dust particles can contaminate products, leading to defects or quality issues. By removing dust from the air, an industrial dust collector ensures that the products maintain high standards of quality and cleanliness.

- Reduced Equipment Maintenance

- Dust can accumulate on machinery, leading to wear and tear, overheating, and equipment failure. By keeping the work area clean and free of dust, industrial dust collectors help reduce the frequency and cost of equipment maintenance and repair.

- Increased Efficiency and Productivity

- Dust accumulation can slow down production, create safety hazards, and reduce the efficiency of machinery. A dust collection system ensures that operations run smoothly without interruption, leading to increased productivity and a more efficient working environment.

- Cost Savings

- Industrial dust collectors are designed to be cost-effective by preventing the need for expensive downtime, repairs, and maintenance. They also minimize material waste by capturing dust that could otherwise be lost, contributing to operational cost savings over time.

Applications of Industrial Dust Collectors

- Woodworking

- Woodworking industries produce large amounts of wood dust, which can pose significant fire and health risks. Industrial dust collectors are used in woodworking shops to collect dust from saws, sanders, and other woodworking machines, improving air quality and reducing fire hazards.

- Metalworking

- In metalworking industries, operations like grinding, sanding, and cutting produce metal dust and particles that can be harmful to workers’ lungs and machinery. Industrial dust collectors are essential for capturing and removing metal dust from the air, ensuring a safer workplace.

- Pharmaceutical Manufacturing

- Pharmaceutical production involves handling fine powders and chemicals that can be harmful if inhaled. Dust collectors in pharmaceutical manufacturing plants prevent airborne particles from contaminating the air, helping to maintain a clean and safe environment for both workers and products.

- Food Processing

- In food processing facilities, dust is often generated from ingredients like flour, sugar, or spices. An industrial dust collector helps remove this dust, preventing contamination, improving air quality, and meeting hygiene standards required in food production.

- Chemical Processing

- Chemical industries handle fine powders, solids, and chemicals that can be dangerous if inhaled. Industrial dust collectors are used to remove these hazardous materials from the air, ensuring the safety of workers and compliance with environmental regulations.

- Cement and Mining

- Dust is commonly generated in cement plants and mining operations, where materials like cement, sand, and rocks are processed. Industrial dust collectors are used to capture and control dust emissions, ensuring cleaner air and protecting workers from the harmful effects of inhaling dust particles.

- Plastic Manufacturing

- Plastic manufacturing processes, such as extrusion and molding, produce significant amounts of dust, particularly from grinding and cutting operations. Dust collection systems are used in these plants to capture dust and particles, reducing health risks and maintaining a clean production environment.

How to Choose the Right Industrial Dust Collector

When selecting an industrial dust collector for your facility, consider the following factors:

- Type of Dust

- Different types of dust (wood, metal, chemical, etc.) require different types of filtration and collection systems. Ensure that the dust collector is suitable for the type of dust generated in your facility.

- Dust Collection Capacity

- The size and scale of your operation will dictate the dust collector’s capacity. Choose a system with enough airflow and dust-holding capacity to meet the needs of your facility.

- Filtration Efficiency

- Look for a dust collector with high-efficiency filtration that meets the standards required for your industry. The system should effectively capture fine dust particles, preventing them from being released into the air.

- Energy Efficiency

- Consider the energy consumption of the dust collection system. Energy-efficient systems can reduce operating costs and minimize environmental impact.

- Maintenance Requirements

- Choose a dust collector that is easy to maintain and clean. Some models offer automatic filter cleaning, which can reduce downtime and maintenance costs.

- Noise Levels

- Some dust collection systems can be loud, which may affect the work environment. Choose a system with noise-reducing features if a quieter operation is important for your facility.

Maintenance Tips for Industrial Dust Collectors

- Regular Filter Inspection and Cleaning

- Filters need to be cleaned or replaced regularly to ensure optimal performance. Check the filters periodically for dust buildup and clean them according to the manufacturer’s guidelines.

- Monitor Airflow

- Check the airflow regularly to ensure that the system is functioning properly. Low airflow could indicate a clog or problem with the ducts or filters.

- Check for Leaks

- Inspect ducts and pipes for leaks that could reduce the system’s efficiency. Repair any leaks promptly to maintain effective dust collection.

- Clean the Dust Bin or Hopper

- Regularly empty the dust collection bin or hopper to prevent overflows and ensure smooth operation.

- Lubricate Moving Parts

- Periodically lubricate fans and other moving parts to reduce friction and ensure efficient operation.

Shot Blasting Machine Point of view

industrial dust collector is an essential system for maintaining a clean and safe working environment in industries where dust is generated. It improves air quality, protects workers’ health, ensures compliance with regulations, and increases overall operational efficiency. By choosing the right dust collection system and maintaining it properly, businesses can reduce health risks, minimize equipment damage, and optimize production processes. Investing in an industrial dust collector is not only a smart choice for ensuring workplace safety but also a cost-effective solution for achieving long-term sustainability in your operations.