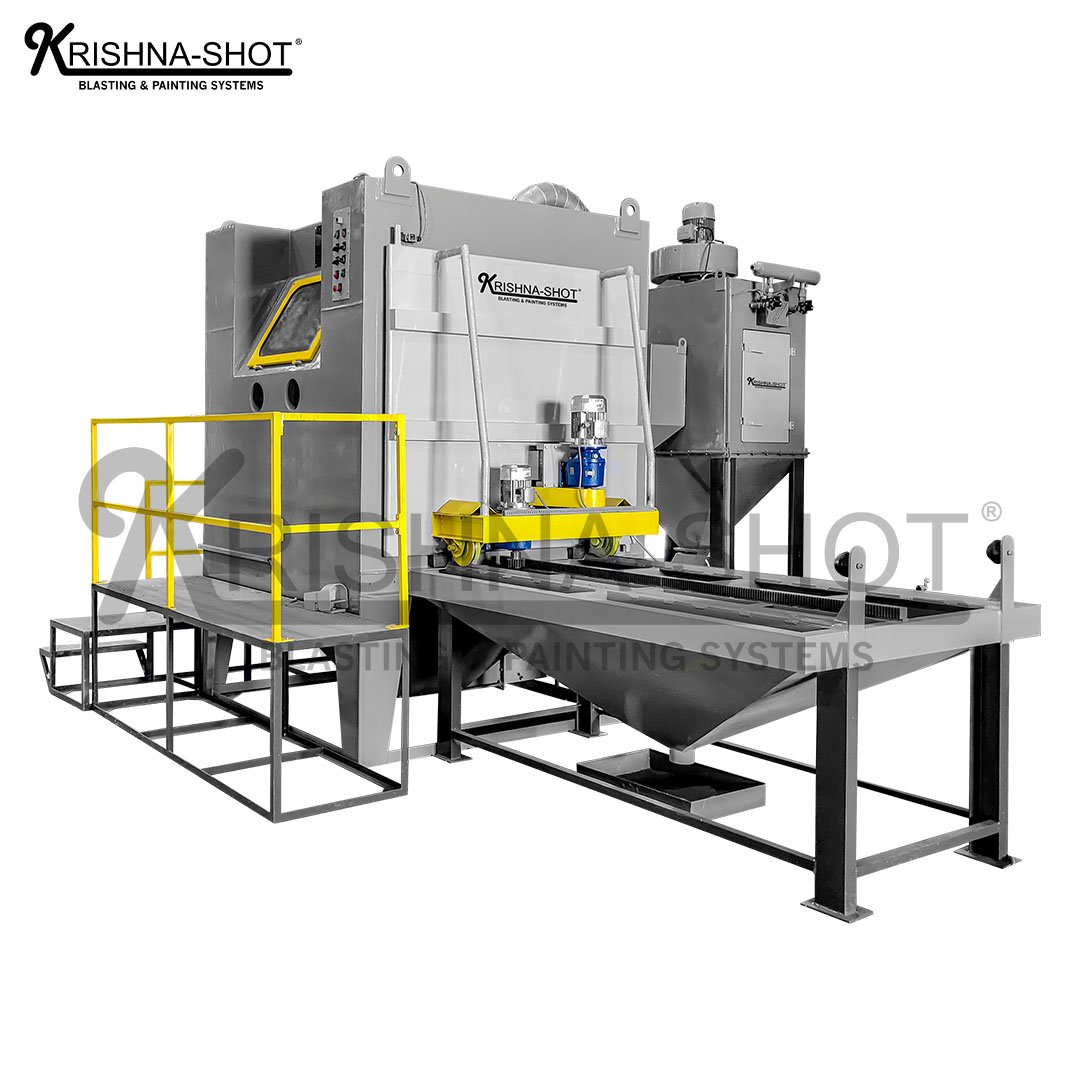

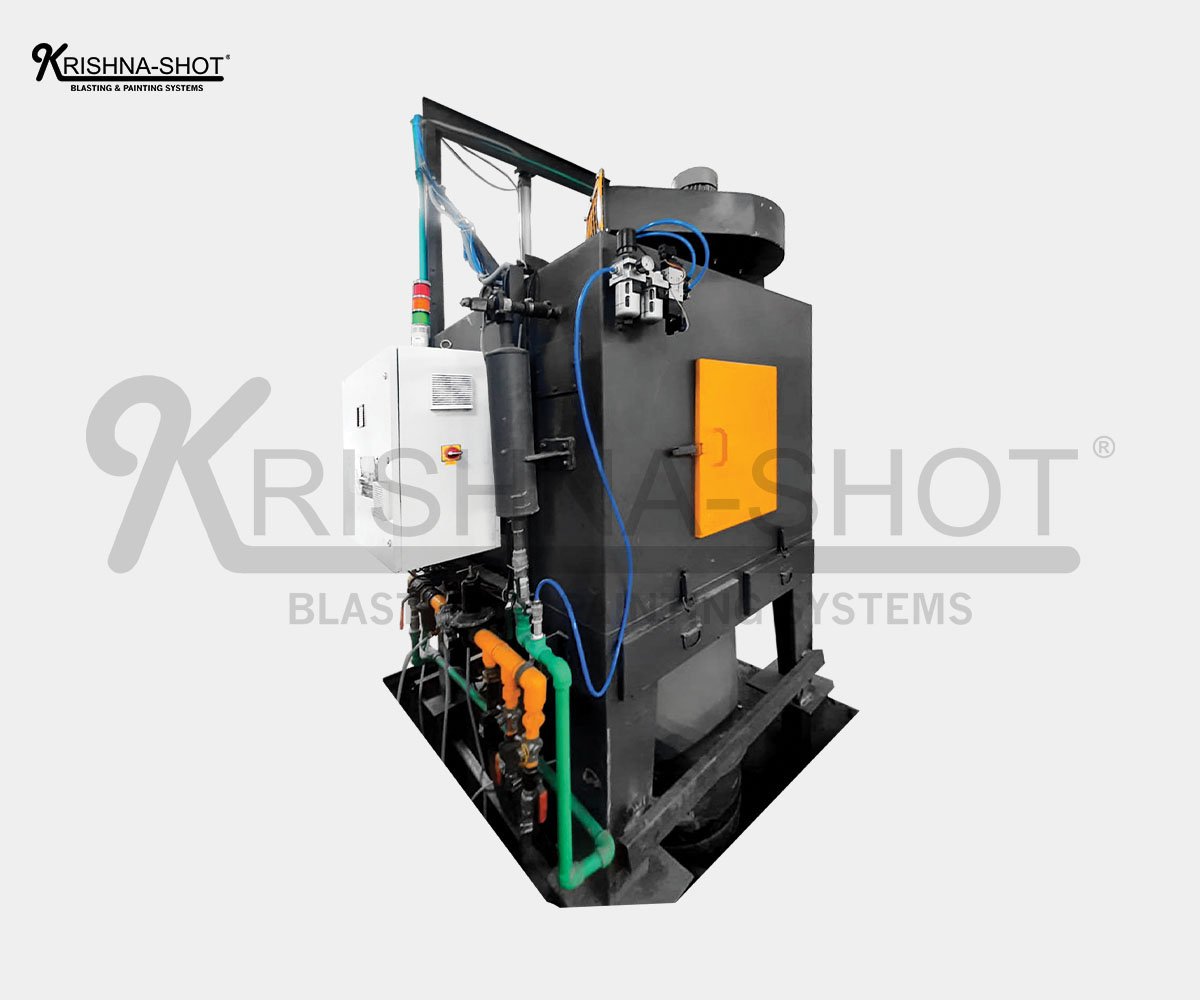

Geyser Shot Blasting Machine

Manufacturer & Supplier Details

- Brand Name: KRISHNA-SHOT®

- Company Name: Krishna Shot Blasting India Pvt. Ltd.

- Experience: 20+ Years in Surface Finishing Solutions

- Verification: Trustseal Verified (Leading Manufacturer & Supplier)

- Delivery Time: Typically 30 Days

- Address: Plot No. 30, Sarita Vihar Nagar, Near Tanawada, Main Salawas Rd, Jodhpur, Rajasthan 342005

- Specialization: Shot Blasting Machines, Blast Rooms, and Paint Booth Systems

- Customer Support: Dedicated after-sales service and technical support

- Certifications: ISO-certified products

Description

Geyser Abrasive Shot Blasting Machine: Specialized Cleaning Solution for Geyser Tanks

The Geyser Abrasive Shot Blasting Machine is a revolutionary system designed specifically for cleaning and preparing the internal surfaces of geyser tanks or water heater tanks. This machine uses high-pressure abrasive media to remove unwanted scale, rust, contaminants, and other residues that accumulate on the internal surfaces of geyser tanks during manufacturing or prolonged use. By ensuring a clean and smooth internal surface, the Geyser Abrasive Shot Blasting Machine plays a critical role in enhancing the efficiency, durability, and overall performance of geysers.

What is the Geyser Abrasive Shot Blasting Machine?

The Geyser Abrasive Shot Blasting Machine is an internal blasting system that specifically targets the cleaning of the interior of geyser tanks. The machine uses abrasive media, such as steel shots or grit, propelled by high-pressure air or centrifugal force, to clean and prepare the internal surfaces of water heater tanks. Unlike traditional shot blasting machines, which clean external surfaces, this specialized machine is designed to reach and thoroughly clean the internal components of geyser tanks, ensuring no contaminants are left that could negatively impact performance.

This specialized blasting process not only cleans but also prepares the surface for further treatments such as coating, preventing rust buildup, and improving the efficiency of heating elements.

Key Features of the Geyser Abrasive Shot Blasting Machine

- Internal Cleaning for Geyser Tanks The primary function of the Geyser Abrasive Shot Blasting Machine is to clean the internal surface of geyser tanks. This ensures the removal of accumulated scale, rust, and other contaminants that can affect the tank’s efficiency and lifespan. The machine’s targeted blasting technology ensures deep penetration into all internal surfaces, reaching areas that are difficult to clean using manual or traditional methods.

- High-Pressure Abrasive Propulsion The Geyser Abrasive Shot Blasting Machine uses high-pressure centrifugal force or air-powered systems to propel abrasive media into the interior of geyser tanks. This creates a powerful jet that removes contaminants from the surface, ensuring a clean, smooth interior without causing damage to the tank itself.

- Precise Blasting Control The machine is equipped with precision controls to adjust the pressure and blasting duration. This allows manufacturers to customize the process based on the specific size and condition of the geyser tank, ensuring consistent and optimal cleaning for tanks of different capacities and designs.

- Abrasive Media Recycling Similar to other industrial shot blasting machines, the Geyser Abrasive Shot Blasting Machine features an abrasive media recovery and recycling system. This system captures and cleans the spent abrasive media, which can be reused multiple times. This not only reduces operational costs but also minimizes waste, making the process more environmentally friendly.

- Dust Collection System To ensure a clean and safe working environment, the Geyser Abrasive Shot Blasting Machine is equipped with a dust collection system that captures the dust and debris generated during the blasting process. This prevents the release of harmful particles into the air, ensuring compliance with safety and environmental regulations.

- Durable and Robust Construction Built to withstand the demanding environment of industrial cleaning, the Geyser Abrasive Shot Blasting Machine is made from high-quality, durable materials that can endure the abrasive impact and harsh conditions of the cleaning process. This ensures long-lasting performance and minimal maintenance.

How Does the Geyser Abrasive Shot Blasting Machine Work?

- Loading the Geyser Tanks The geyser tanks are loaded into the blasting chamber, either manually or via an automated system. Depending on the design of the machine, multiple tanks can be processed in one cycle, improving throughput and efficiency.

- Internal Blasting Process Once the tank is loaded, the blasting system is activated. High-pressure abrasive media is directed into the interior of the geyser tank, where it impacts the inner walls, removing scale, rust, and other contaminants. The intense pressure and movement of the media ensure complete cleaning, reaching all areas inside the tank.

- Media Impact and Surface Cleaning The abrasive particles collide with the surface, effectively removing accumulated residues. This not only cleans the tank but also helps to prepare the surface for coating or further processing, enhancing the tank’s performance and durability.

- Recycling of Abrasive Media After the cleaning process is complete, the spent abrasive media is collected and sent to a recovery system. The media is cleaned and separated from contaminants, ready to be reused for future blasting cycles. This closed-loop system reduces waste and operational costs.

- Dust Collection and Filtration During the blasting process, dust and small particles are generated. The dust collection system ensures that these particles are captured and filtered out of the air, maintaining a clean working environment and ensuring operator safety.

- Unloading the Cleaned Geyser Tanks After the internal surfaces of the geyser tank are thoroughly cleaned, the machine completes the cycle. The cleaned geyser tanks are then unloaded, ready for further processing, such as coating, painting, or installation of heating elements.

Applications of the Geyser Abrasive Shot Blasting Machine

- Manufacturing of Geysers The Geyser Abrasive Shot Blasting Machine is essential in the manufacturing process of geysers. It ensures that the interior of water heater tanks is completely clean before they undergo further treatments such as coating or welding. This step is crucial for preventing corrosion and improving the overall performance of the geyser.

- Rust and Scale Removal Over time, rust, scale, and mineral deposits accumulate inside geyser tanks due to frequent use. The Geyser Abrasive Shot Blasting Machine is used to remove these deposits, restoring the interior surfaces and improving the geyser’s energy efficiency.

- Coating and Surface Preparation Before applying internal coatings or protective layers, the surface of the geyser tank must be thoroughly cleaned. The Geyser Abrasive Shot Blasting Machine ensures that the internal surface is free of contaminants, providing a smooth, clean surface for better adhesion of coatings and paints.

- Maintenance of Geysers For maintenance and refurbishment purposes, the Geyser Abrasive Shot Blasting Machine can be used to clean older geysers. This process helps to extend the lifespan of geysers by removing corrosion, scale, and other residues that may hinder their operation.

Benefits of the Geyser Abrasive Shot Blasting Machine

- Improved Cleaning Efficiency The Geyser Abrasive Shot Blasting Machine provides uniform and thorough cleaning of the internal surfaces of geyser tanks, ensuring that all areas are effectively treated, including difficult-to-reach spots that are typically challenging to clean manually.

- Enhanced Performance and Longevity By removing rust, scale, and other contaminants, the machine helps to prevent future damage and corrosion, improving the performance and longevity of geysers. Clean internal surfaces also contribute to more efficient heating, reducing energy consumption.

- Cost-Effective Operation The integrated abrasive media recycling system helps reduce operational costs by reusing the blasting media, making the cleaning process more cost-efficient. The reduction in abrasive media consumption also lowers waste production, benefiting the environment.

- Safer and Cleaner Work Environment The dust collection system ensures that hazardous dust and particles generated during the blasting process are captured and filtered, improving workplace safety and maintaining a clean and healthy environment for operators.

- Better Coating and Painting Adhesion A clean internal surface is essential for better adhesion of protective coatings or paints. The Geyser Abrasive Shot Blasting Machine prepares the tank’s interior surface for better coating adhesion, which in turn increases the geyser’s resistance to corrosion.

Conclusion

The Geyser Abrasive Shot Blasting Machine is a specialized tool for cleaning the internal surfaces of geyser tanks. With its high-pressure abrasive blasting technology, it ensures the removal of scale, rust, and other contaminants, improving the performance, longevity, and efficiency of geysers. Whether used in the manufacturing process, maintenance, or refurbishment of water heaters, this machine offers a cost-effective, environmentally friendly solution for maintaining high standards of cleanliness and quality in geyser production. Its advanced features, such as precise blasting control, abrasive media recycling, and dust collection, make it a vital component in modern industrial settings focused on producing durable and high-performance geysers.