Paint Drying Oven

Manufacturer & Supplier Details

- Brand: KRISHNA-SHOT®

- Company: Krishna Shot Blasting India Pvt. Ltd.

- Experience: 20+ Years in Surface Finishing Solutions

- Verification: Trustseal Verified (Leading Manufacturer & Supplier)

- Delivery Time: Typically 30 Days

- Address: Plot No. 30, Sarita Vihar Nagar, Near Tanawada, Main Salawas Rd, Jodhpur, Rajasthan 342005

- Specialization: Shot Blasting Machines, Blast Rooms, and Paint Booth Systems

- Turnkey Project : Full Plant Setup | Shot Blasting & Painting System

- Customer Support: Dedicated after-sales service and technical support

- Certifications: ISO-certified products (if applicable)

Category: Industrial oven

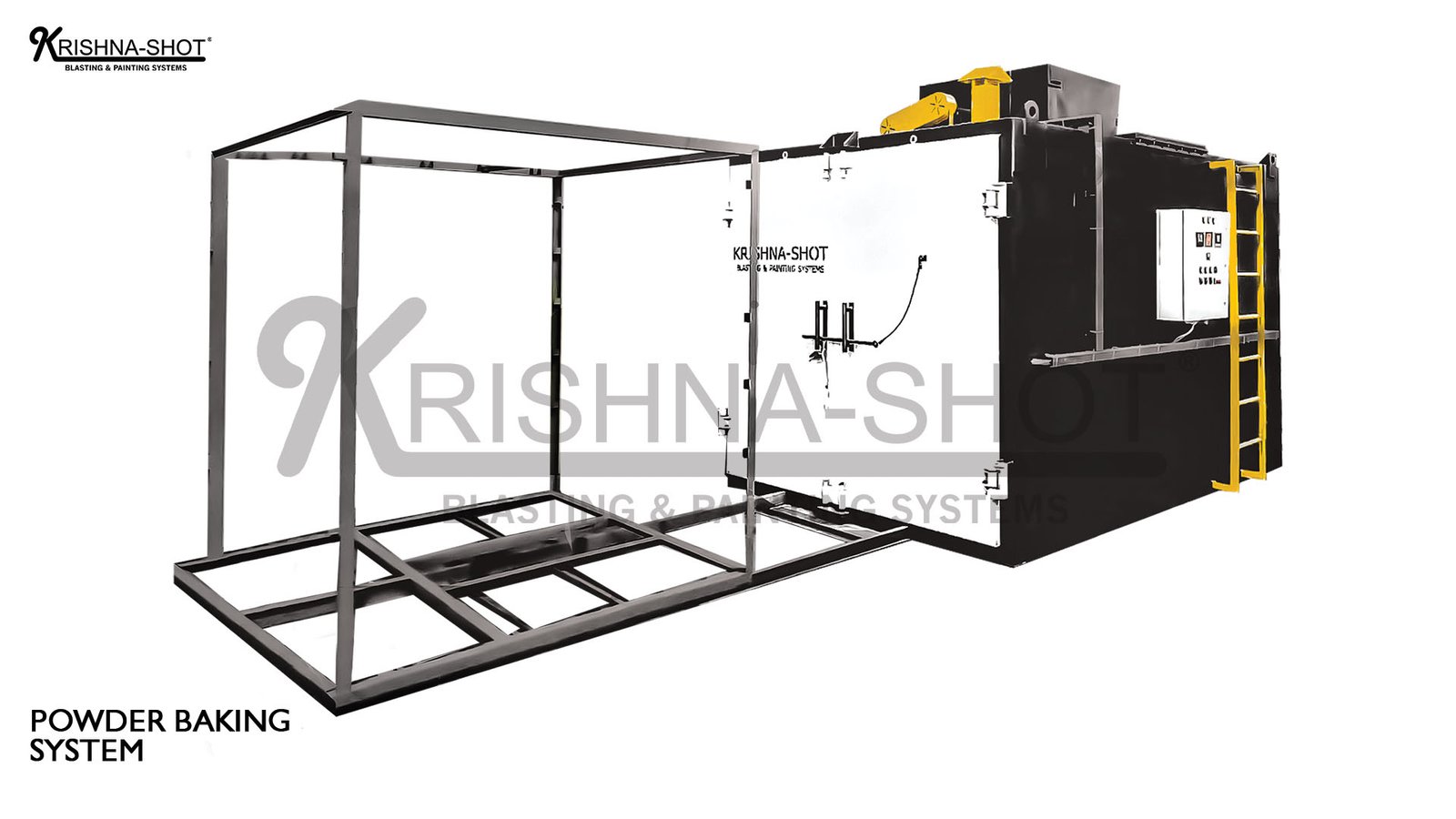

Tags: Drying Ovens, oven, Paint Drying Ovens, Paint Ovens, powder coating system

Description

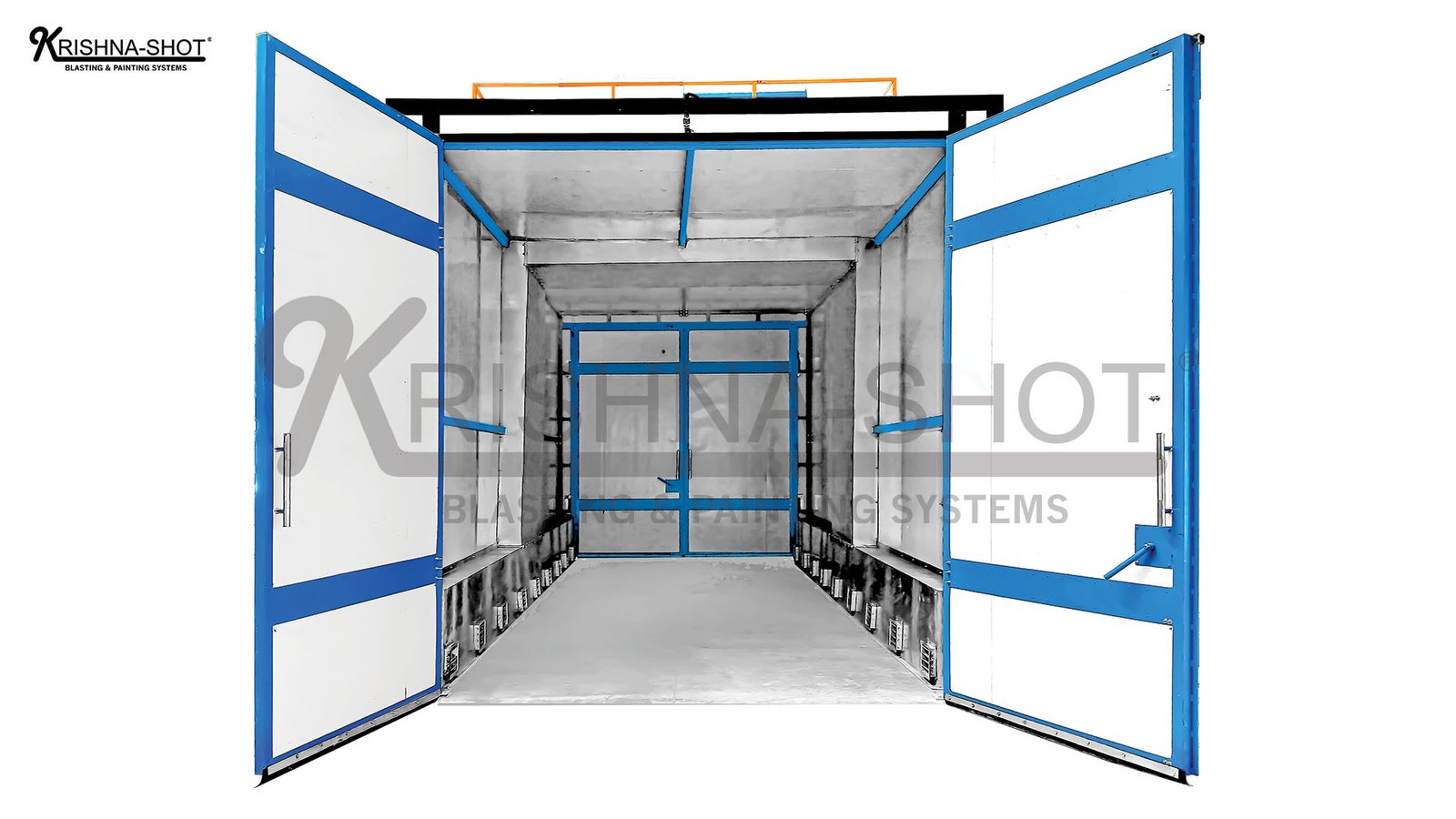

Paint Drying Oven

Paint Drying Oven is a vital equipment in industrial settings, designed to cure or dry painted or coated surfaces efficiently. These ovens offer precise control over temperature and airflow, ensuring that paint or coatings dry evenly, enhancing the quality of finishes and reducing production time. Our Paint Drying Ovens are built for various applications, including automotive, metalworking, and furniture industries, where fast and effective drying of painted surfaces is crucial.

Key Features of Paint Drying Ovens

- Uniform Temperature Control: Ensures consistent temperature throughout the chamber for even drying and curing of paint or coatings.

- Energy Efficient: Equipped with advanced heating technologies, the ovens are designed to minimize energy consumption while providing maximum drying performance.

- Adjustable Temperature and Airflow: Offers precise control over temperature and airflow, allowing users to customize the drying process to suit different coatings and materials.

- Durable Construction: Built with high-quality materials, the ovens are designed for long-lasting durability, withstanding high operational temperatures and heavy-duty use.

- Fast Drying Time: Reduces drying times significantly, speeding up production processes and improving operational efficiency.

- User-Friendly Interface: Simple controls and digital displays make it easy for operators to adjust settings and monitor performance.

- Safe Operation: Equipped with safety features such as automatic shut-off systems, over-temperature protection, and proper ventilation for enhanced user safety.

- Environmentally Friendly: Designed with energy-saving features and eco-friendly heating systems, minimizing the environmental impact of the drying process.

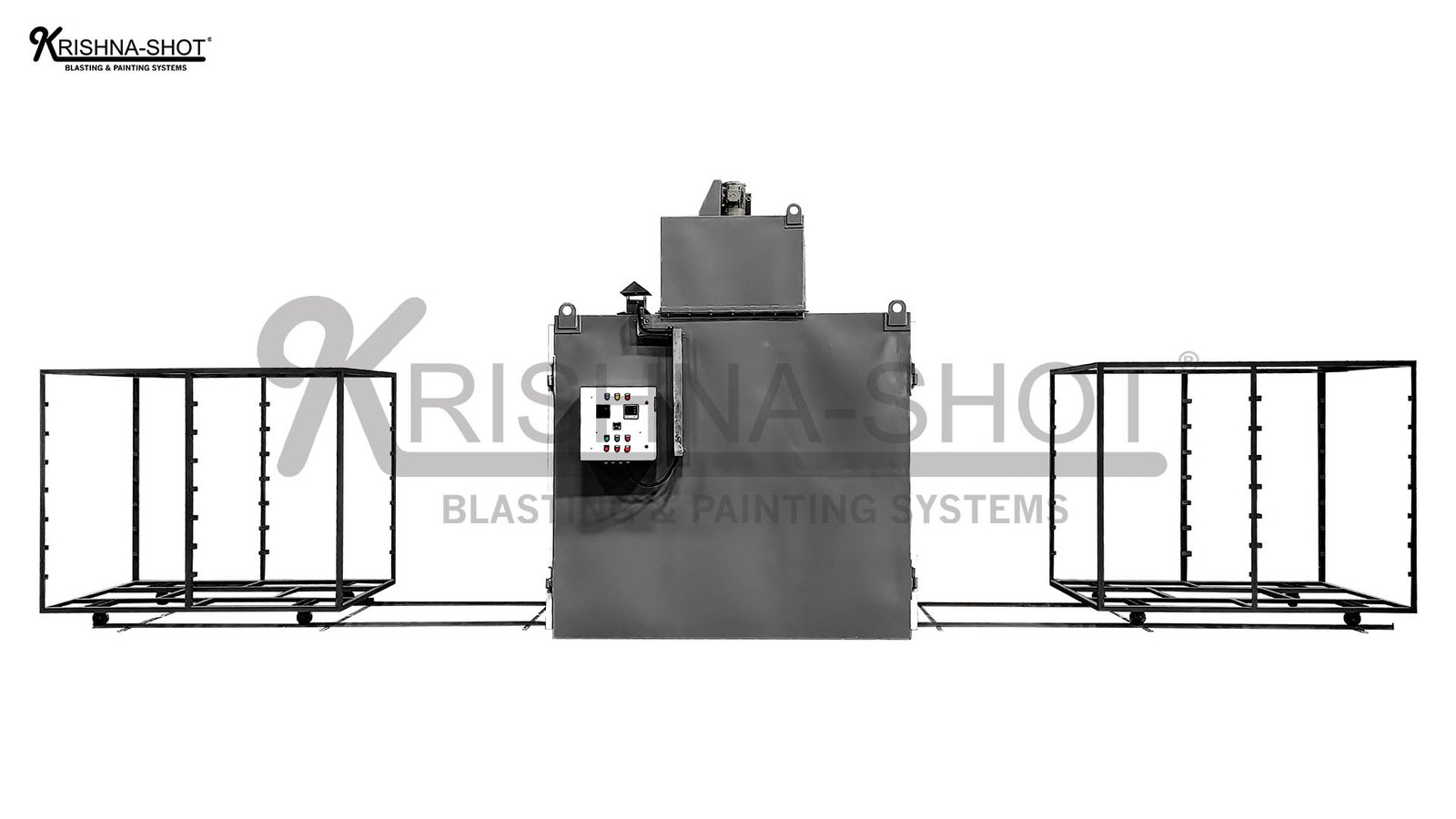

Types of Paint Drying Ovens

- Electric Paint Drying Oven

Uses electric heating elements to generate heat and is ideal for smaller operations or where gas supply is not available. - Gas Paint Drying Oven

Powered by gas, these ovens are more energy-efficient for larger operations, offering faster heating and high throughput. - Conveyorized Paint Drying Oven

Ideal for high-volume operations, these ovens are designed to accommodate conveyor systems, allowing for automated and continuous drying of painted items. - Batch Paint Drying Oven

Perfect for medium-sized batches, these ovens allow multiple items to be dried at once, providing flexibility and efficient drying for various sizes of workpieces. - Infrared Paint Drying Oven

Uses infrared radiation to dry the painted surface quickly, reducing drying time and energy consumption.

Applications of Paint Drying Ovens

- Automotive Industry: Drying painted vehicle parts, chassis, and body components.

- Furniture Industry: Curing coatings on wooden or metal furniture for a durable and high-quality finish.

- Metal Coatings: Ideal for curing powder coatings and other metal finishing treatments.

- Appliance Industry: Drying painted or coated components used in household appliances like refrigerators, washing machines, and ovens.

- General Manufacturing: Used for curing and drying coatings on a variety of products across industries.

Benefits of Paint Drying Ovens

- Faster Production: Reduces the time required for drying and curing, improving the overall efficiency of production lines.

- Improved Finish Quality: Ensures that the paint or coating is uniformly dried, reducing defects and ensuring a high-quality finish.

- Cost-Effective: With energy-efficient heating and faster drying times, these ovens lower operational costs in the long run.

- Enhanced Durability: The uniform curing process ensures that the coating is long-lasting and resistant to wear and tear.

- Customization Options: Our ovens can be tailored to meet specific requirements for different industries, materials, and product sizes.