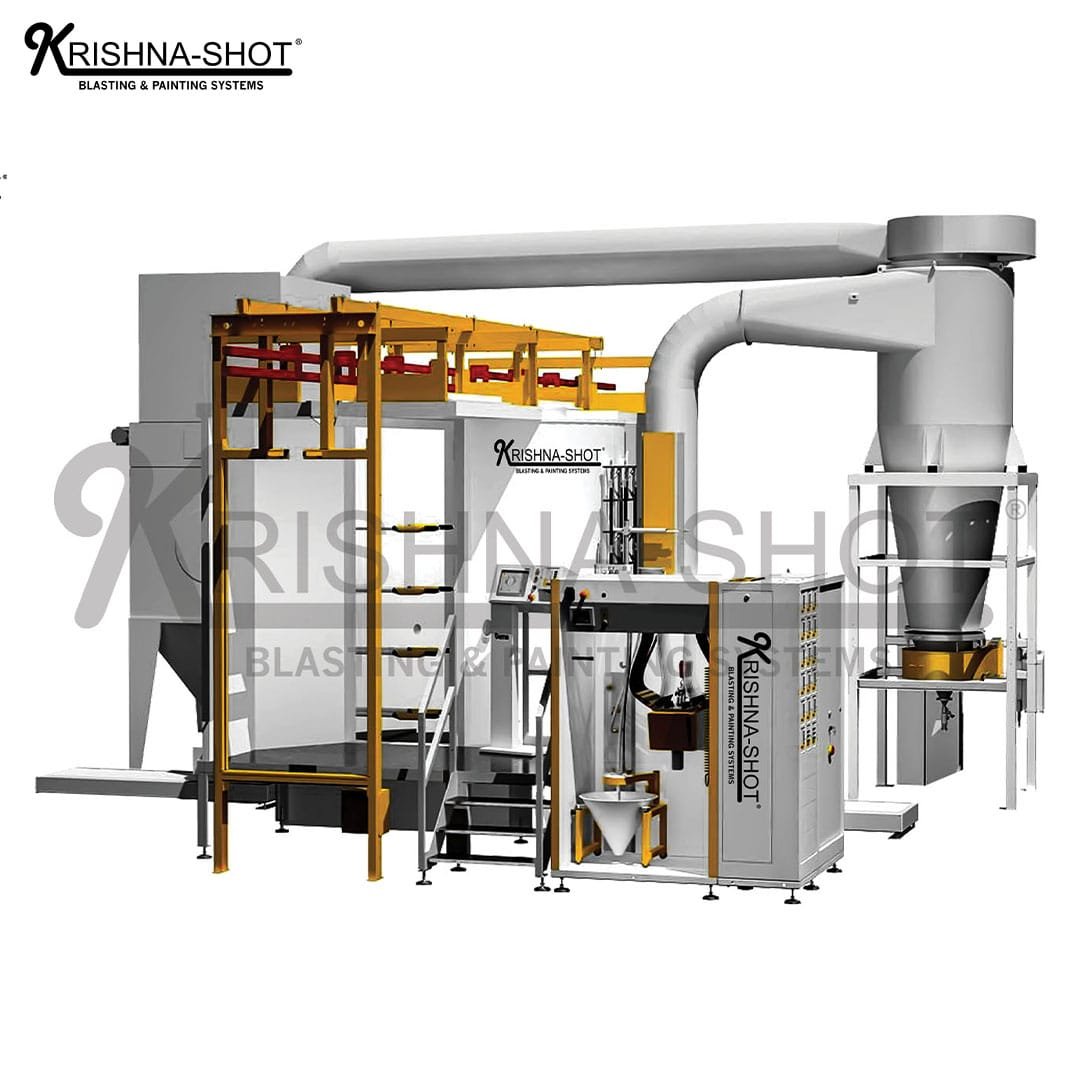

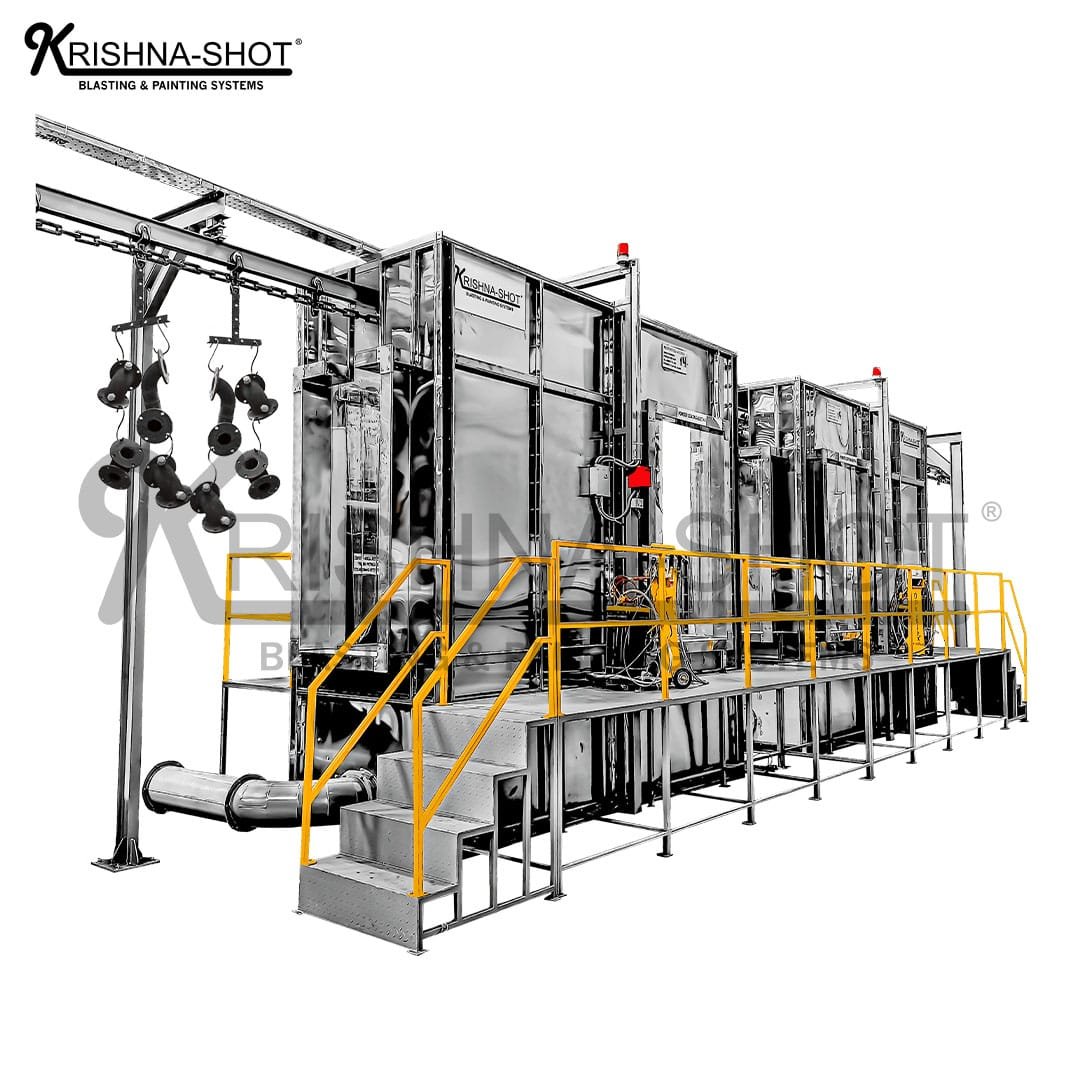

Powder Coating System | Semi Automatic

Semi-Automatic Powder Coating System combines the precision and consistency of automated processes with the flexibility of manual control, providing an ideal solution for businesses that need both efficiency and custom application capabilities. This system is perfect for applications requiring high-quality finishes and can handle a variety of part sizes and shapes.

Key Features:

- Versatile Application: Suitable for a wide range of metal and other components, the semi-automatic system ensures an even and smooth coating on various surfaces, providing a professional finish.

- Efficiency and Control: Operators have the flexibility to adjust the coating process, allowing for more customized results while still benefiting from semi-automation. The system balances manual adjustments with automation for greater control over the coating quality.

- Cost-Effective: With automated processes, the Semi-Automatic Powder Coating System minimizes manual labor, leading to reduced labor costs while maintaining high coating efficiency. It is perfect for small to medium-sized production runs.

- High-Quality Finish: The system delivers excellent durability, resistance to corrosion, and a smooth, even finish on every part. It ensures that products have the required aesthetic and functional qualities.

- Energy-Efficient: The system uses advanced technology to optimize energy consumption during the coating and curing process, lowering operational costs.

- User-Friendly: With simple controls and easy maintenance, operators can quickly learn how to use the system, resulting in minimal downtime and maximum productivity.

- Customizable: The semi-automatic system allows adjustments to powder feed, air pressure, and curing time to meet the specific needs of different parts and coatings.

Applications:

- Automotive components requiring high-performance finishes.

- Industrial equipment and parts that need corrosion resistance and durability.

- Electronics parts requiring both functional coatings and aesthetic finishes.

- Manufacturing of furniture and other metal items that require an attractive and resilient surface.

Benefits:

- Fast application and efficient use of powder material.

- Customizable process for tailored results.

- Cost-effective solution for small to medium-sized runs.

- Reduced operational costs with energy-efficient features.