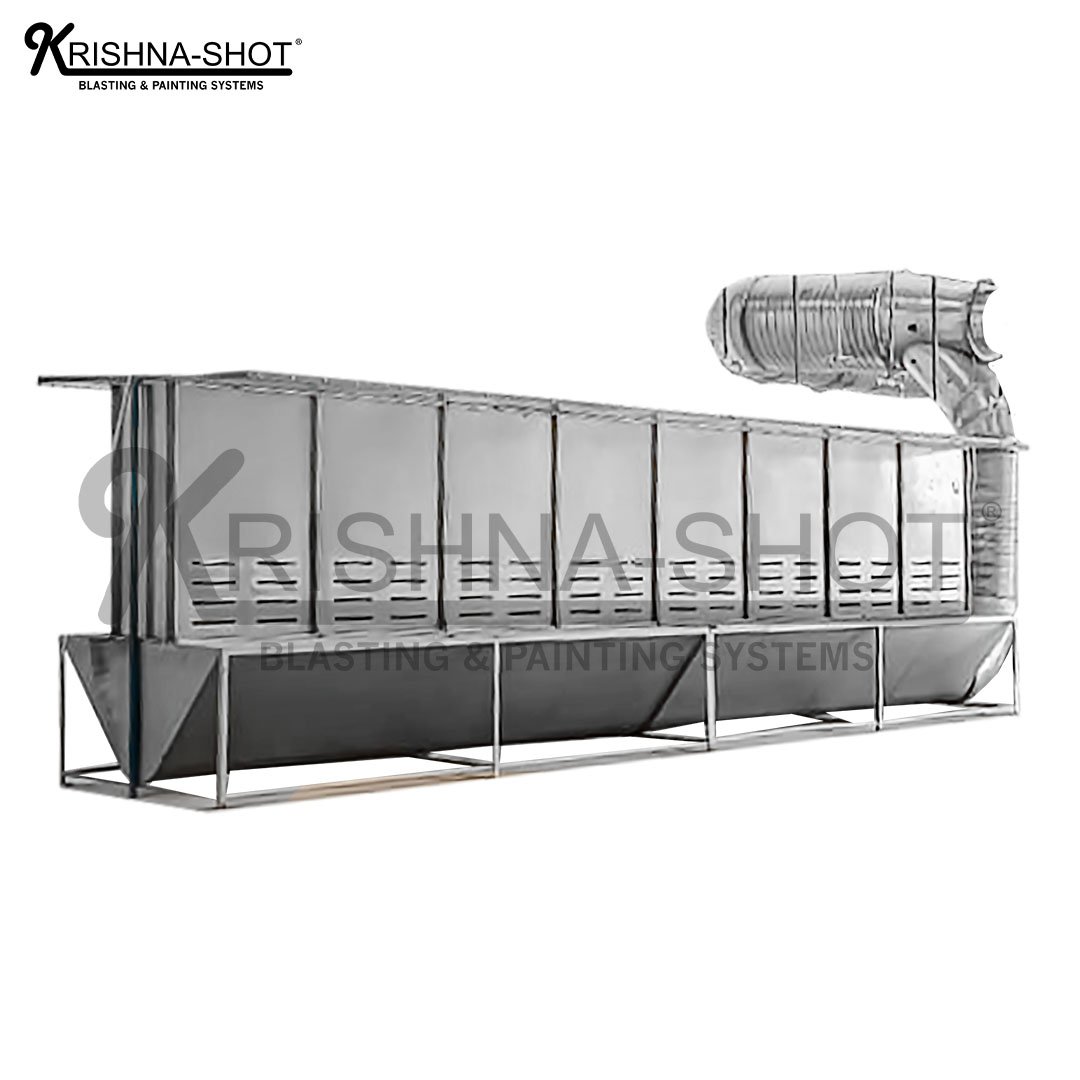

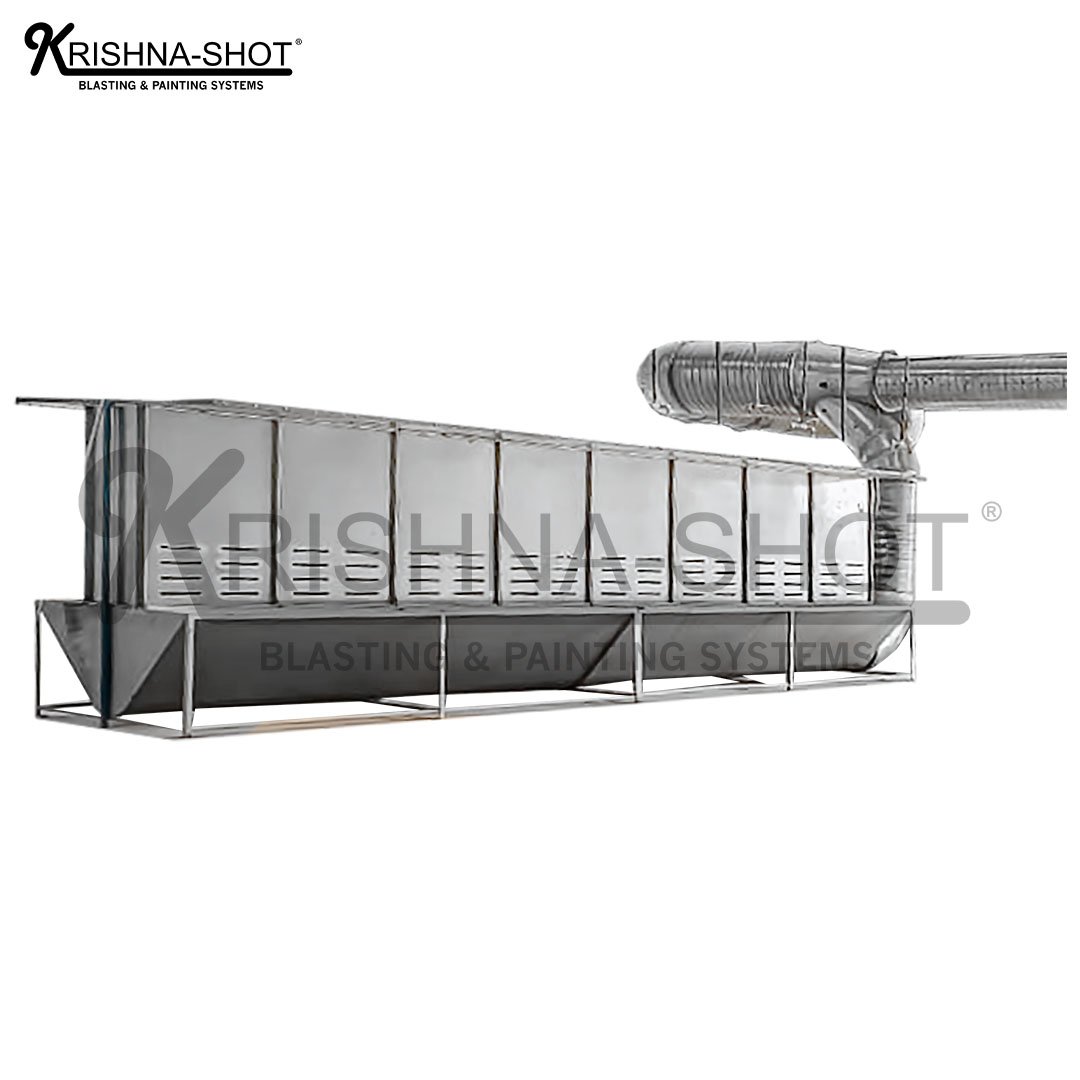

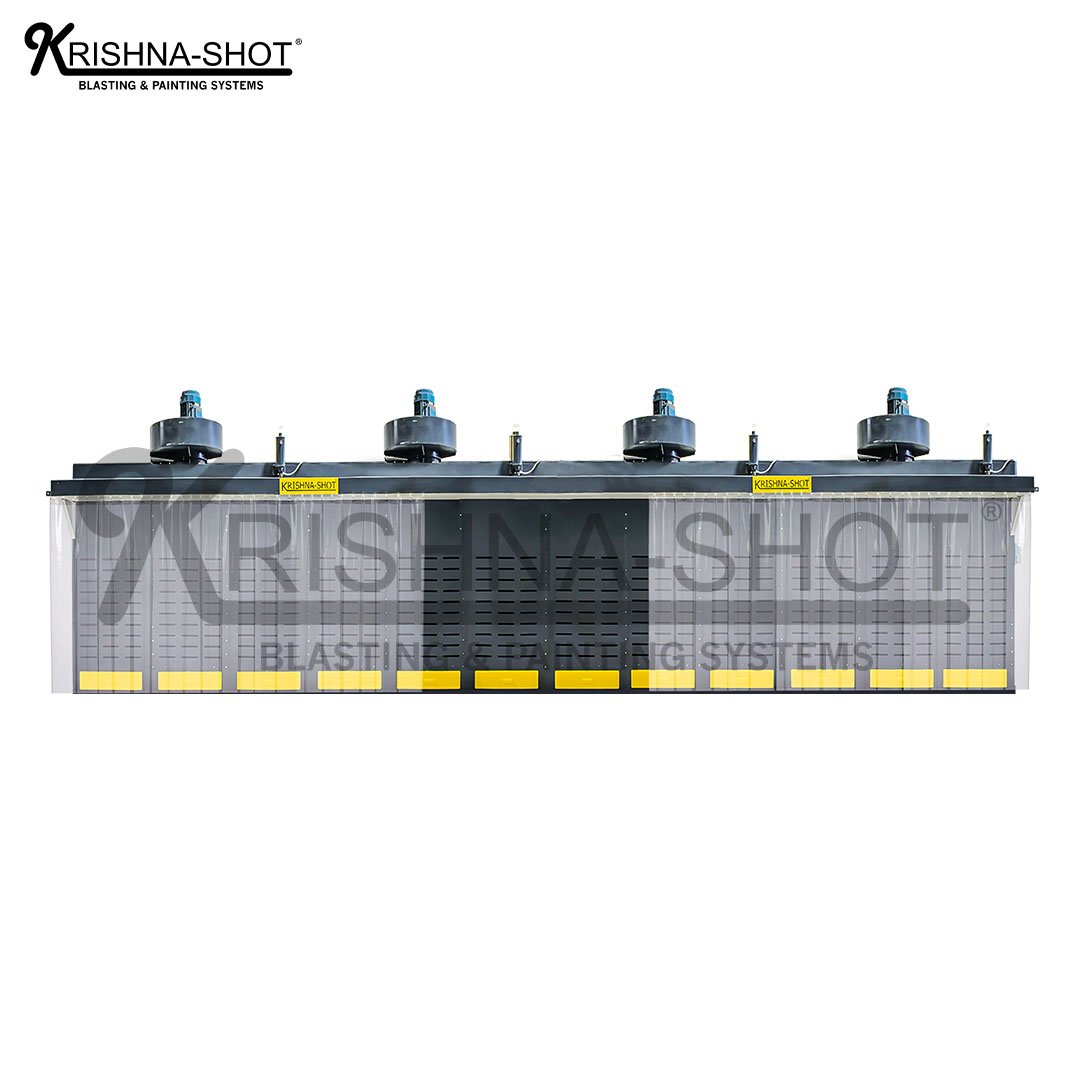

Sanding booth

Manufacturer & Supplier Details

- Brand Name: KRISHNA-SHOT®

- Company Name: Krishna Shot Blasting India Pvt. Ltd.

- Experience: 20+ Years in Surface Finishing Solutions

- Verification: Trustseal Verified (Leading Manufacturer & Supplier)

- Delivery Time: Typically 30 Days

- Address: Plot No. 30, Sarita Vihar Nagar, Near Tanawada, Main Salawas Rd, Jodhpur, Rajasthan 342005

- Specialization: Shot Blasting Machines, Blast Rooms, and Paint Booth Systems

- Customer Support: Dedicated after-sales service and technical support

- Certifications: ISO-certified products

Description

Sanding Booth: An Ideal Solution for Dust-Free Sanding Operations

sanding booth is a specialized enclosure designed to provide a clean and controlled environment for sanding operations. It is widely used in industries such as woodworking, automotive, metal fabrication, and aerospace. The primary purpose of a sanding booth is to capture dust, debris, and airborne particles generated during sanding, ensuring worker safety, maintaining product quality, and complying with environmental regulations.

Features of a Sanding Booth

A sanding booth is equipped with advanced features that make it an efficient solution for sanding tasks. Key components typically include:

- Ventilation System

- A high-powered ventilation system ensures that dust and debris are extracted from the air during sanding operations. This prevents the accumulation of fine particles, which can affect air quality and worker health.

- Dust Collection System

- An integrated dust collection unit captures and stores particles, preventing them from being released into the environment. Some booths come with HEPA filters for maximum dust filtration.

- Lighting

- Bright, well-placed lighting provides optimal visibility, enabling workers to perform precision sanding and identify imperfections on surfaces.

- Soundproofing

- Sanding booths often include soundproofing materials to minimize noise levels during operation, creating a more comfortable working environment.

- Adjustable Workspaces

- Some sanding booths feature adjustable work tables or platforms to accommodate various product sizes and ensure ergonomic working conditions.

- Modular Design

- Many sanding booths are modular and can be customized in size and layout to meet the specific requirements of different industries or production lines.

Benefits of a Sanding Booth

Using a sanding booth offers numerous advantages, including:

- Improved Air Quality

- The powerful dust collection and ventilation systems ensure that airborne particles are removed efficiently, creating a safer and cleaner workspace.

- Worker Safety

- By minimizing exposure to fine dust and harmful particles, sanding booths protect workers from respiratory issues and other health risks associated with prolonged exposure to dust.

- Enhanced Product Quality

- A dust-free environment ensures that sanding imperfections are minimized, resulting in a smoother and more uniform surface finish.

- Compliance with Regulations

- Sanding booths help industries meet stringent environmental and workplace safety standards, reducing the risk of penalties.

- Cost Savings

- With efficient dust capture and reduced waste, sanding booths lower cleanup costs and enhance the longevity of tools and equipment.

- Versatility

- Sanding booths can handle a wide range of materials, including wood, metal, plastic, and composites, making them suitable for various applications.

Applications of Sanding Booths

Sanding booths are used in a variety of industries, including:

- Automotive Industry

- Preparing car panels, bumpers, and other components for painting and finishing.

- Woodworking

- Smoothing wood surfaces for furniture, cabinetry, and decorative items.

- Metal Fabrication

- Polishing and sanding metal components for industrial machinery, tools, and equipment.

- Aerospace

- Preparing aircraft parts for coating, painting, or assembly.

- Construction

- Finishing materials like drywall, concrete, or other building elements.

Types of Sanding Booths

Different types of sanding booths are available based on specific requirements:

- Dry Sanding Booth

- Uses a dry filtration system to capture dust. Ideal for industries working with wood, metal, or composites.

- Wet Sanding Booth

- Equipped with water filtration systems to trap airborne particles. Commonly used for applications requiring precision and minimal dust exposure.

- Portable Sanding Booth

- A mobile solution for smaller operations or on-site sanding tasks, offering flexibility without compromising on dust control.

- Custom Sanding Booth

- Tailored to meet specific industry or production needs, including size, filtration type, and workspace layout.

How to Choose the Right Sanding Booth

When selecting a sanding booth, consider the following factors:

- Industry Requirements

- Determine the materials and types of sanding processes your industry handles. For instance, woodworking may require a dry booth, while automotive work may benefit from a wet sanding booth.

- Size

- Choose a booth size that accommodates your workspace and the dimensions of the products being sanded.

- Filtration System

- Ensure the booth has an efficient filtration system, such as HEPA filters, to meet environmental standards and ensure proper dust capture.

- Custom Features

- Consider additional features like adjustable tables, soundproofing, or enhanced lighting for better functionality.

- Durability and Maintenance

- Optimize for a durable and easy-to-maintain design that can withstand frequent use and provide reliable performance over time.

Maintenance Tips for Sanding Booths

To ensure your sanding booth operates efficiently and lasts longer, follow these maintenance tips:

- Regularly Clean Filters: Clean or replace dust filters periodically to maintain optimal performance.

- Inspect Ventilation Systems: Check for blockages or wear and tear in ventilation components to ensure effective airflow.

- Maintain Lighting: Replace worn or dim lights to maintain visibility during operations.

- Schedule Routine Checks: Conduct regular inspections of all components to identify and address issues early.

Shot Blasting Machine Point of view

sanding booth is an essential solution for industries that require clean and efficient sanding operations. By providing a dust-free environment, ensuring worker safety, and enhancing product quality, sanding booths play a critical role in modern manufacturing and finishing processes. Whether you’re in the automotive, woodworking, or metal fabrication industry, investing in a high-quality sanding booth can streamline your operations, improve outcomes, and maintain compliance with safety and environmental standards.