Sanding Suction Wall

Manufacturer & Supplier Details

- Brand Name: KRISHNA-SHOT®

- Company Name: Krishna Shot Blasting India Pvt. Ltd.

- Experience: 20+ Years in Surface Finishing Solutions

- Verification: Trustseal Verified (Leading Manufacturer & Supplier)

- Delivery Time: Typically 30 Days

- Address: Plot No. 30, Sarita Vihar Nagar, Near Tanawada, Main Salawas Rd, Jodhpur, Rajasthan 342005

- Specialization: Shot Blasting Machines, Blast Rooms, and Paint Booth Systems

- Customer Support: Dedicated after-sales service and technical support

- Certifications: ISO-certified products

Description

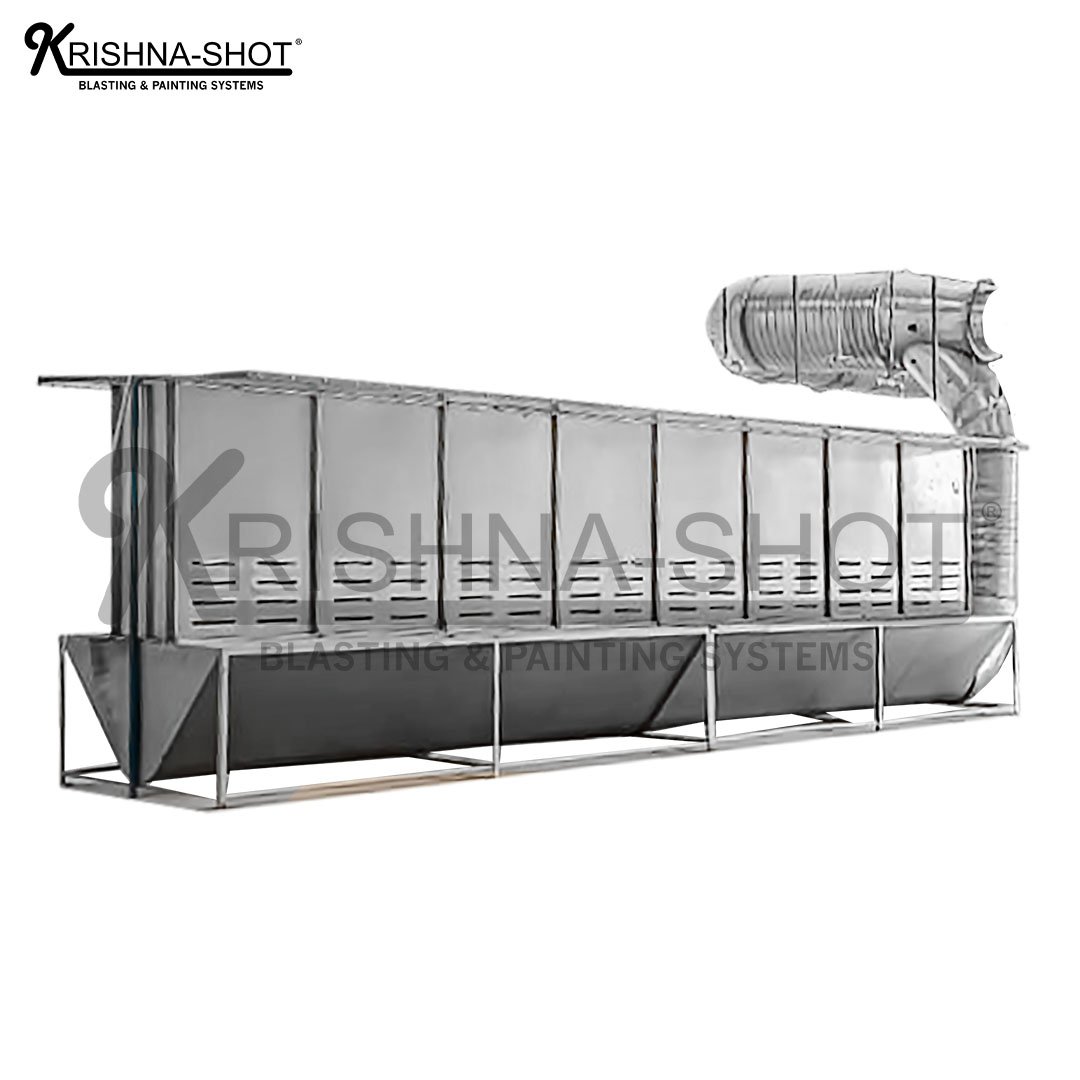

Sanding Suction Wall

Sanding Suction Wall is an innovative dust and debris management system specifically designed for industrial applications where sanding, grinding, or similar operations are performed. This system plays a critical role in maintaining a clean and safe workspace by effectively collecting dust, debris, and other particles generated during these processes. Its robust design, efficient filtration, and ease of use make it an indispensable tool in industries such as furniture manufacturing, automotive workshops, and metal fabrication units.

How the Sanding Suction Wall Works

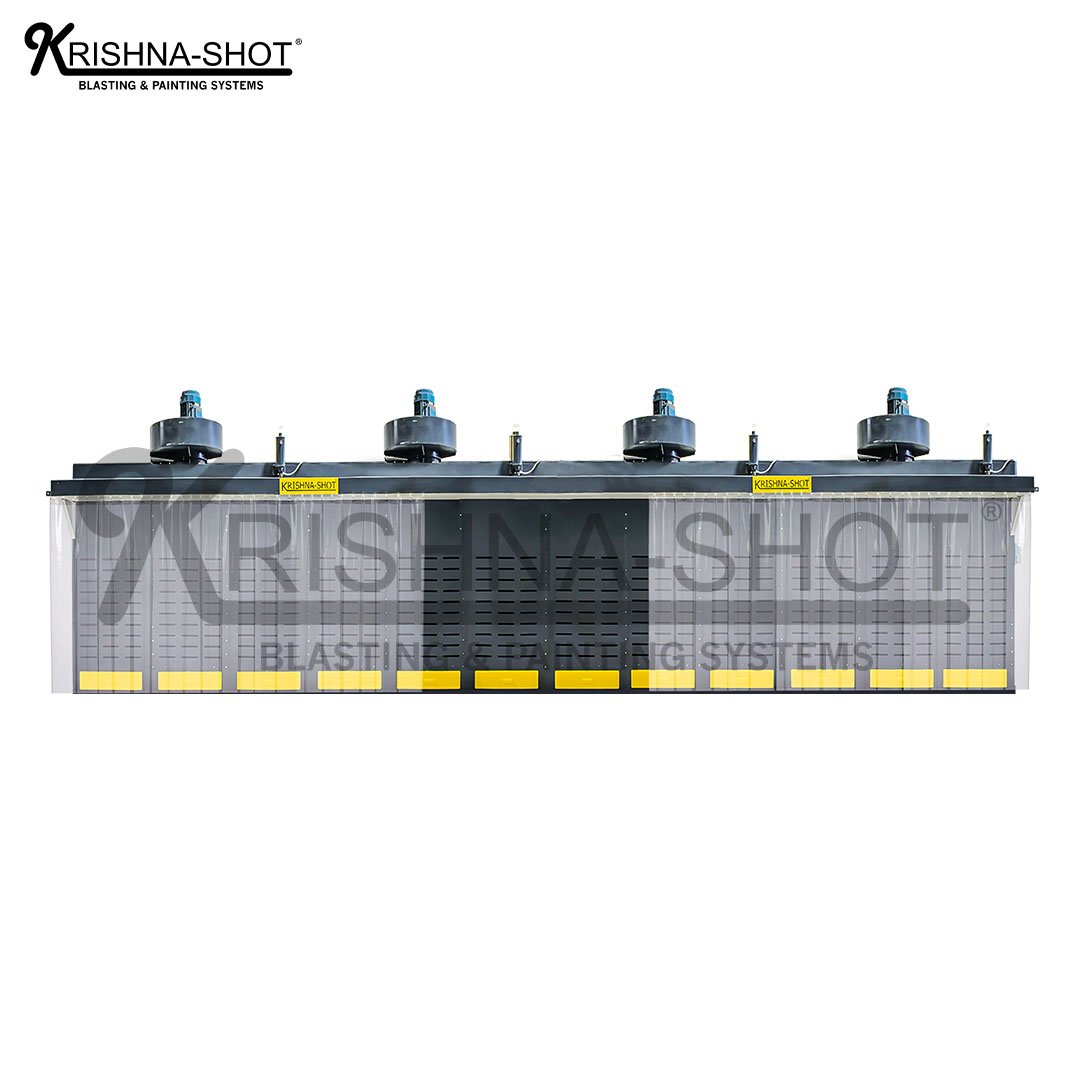

The Sanding Suction Wall functions as an advanced dust collector integrated into a wall-like structure. The system is equipped with high-capacity suction fans and a series of replaceable filters. Here’s how it operates:

- Suction Mechanism: The high-powered fans create a strong suction force, drawing in airborne dust, particles, and debris generated during sanding, grinding, or polishing operations.

- Filtration: The particles are passed through multiple layers of filters that effectively trap even the finest dust. These filters are specially designed to ensure maximum air purification while maintaining optimal airflow.

- Clean Air Release: Once the dust and debris are collected, the cleaned air is released back into the workspace, maintaining a safe and breathable environment.

- Dust Collection Bin: The collected dust and particles are stored in removable bins located at the bottom of the wall. These bins are easy to access and clean, ensuring hassle-free maintenance.

Key Features of Sanding Suction Wall

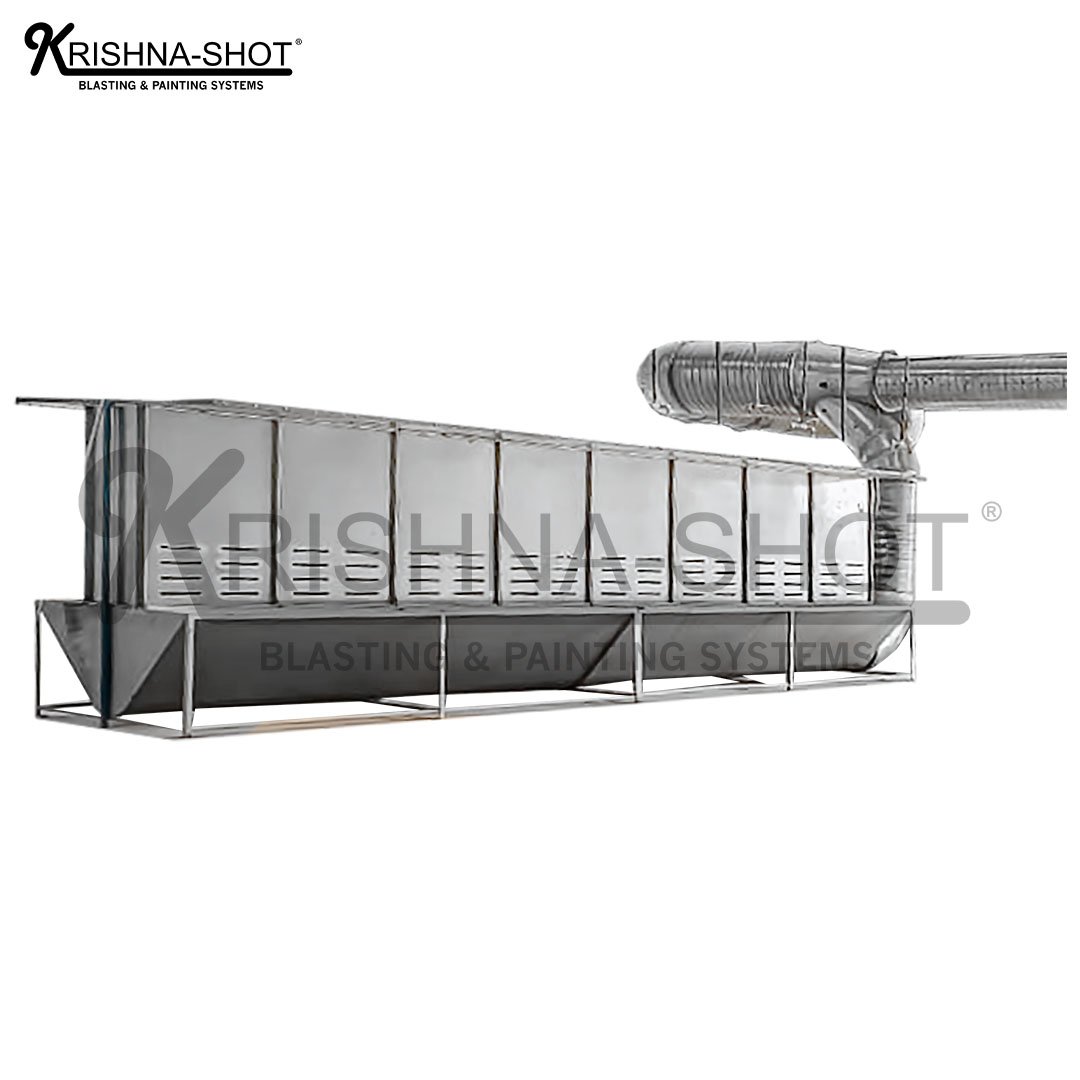

- Wall-Integrated Design:

The Sanding Suction Wall is designed as a vertical structure, allowing workers to perform their tasks close to the system. This minimizes the spread of dust in the workspace. - High-Efficiency Suction:

The powerful suction fans ensure that dust and debris are captured at the source, reducing the risk of airborne contamination. - Advanced Filtration System:

The multi-layer filtration system ensures that even microscopic particles are effectively captured, promoting a healthier work environment. - Durable and Robust Construction:

Built from high-quality materials, the Sanding Suction Wall is designed to withstand demanding industrial environments while maintaining consistent performance. - Low Maintenance:

The system features easy-to-clean filters and removable dust collection bins, making maintenance quick and straightforward. - Noise Reduction:

Despite its powerful suction capabilities, the system operates with minimal noise, enhancing the comfort of the workspace. - Customizable Options:

The system can be customized in terms of size, suction power, and filtration capacity to meet the specific needs of various industries.

Applications of Sanding Suction Wall

The Sanding Suction Wall is a versatile solution for industries where sanding, grinding, and polishing generate significant dust and debris. Key applications include:

- Furniture Manufacturing:

Captures wood dust and particles generated during sanding and polishing operations, ensuring a clean and safe environment for workers. - Metal Fabrication:

Collects metallic dust and fine debris produced during grinding or surface finishing of metal components. - Automotive Workshops:

Ideal for capturing paint dust, sanding debris, and other particles during vehicle repair and finishing processes. - Industrial Plants:

Suitable for heavy-duty operations where dust and particles are consistently generated during machining or fabrication tasks.

Benefits of Sanding Suction Wall

- Improved Air Quality:

By capturing dust and debris at the source, the system significantly enhances air quality, reducing health hazards for workers. - Enhanced Worker Safety:

Minimizes exposure to harmful particles, preventing respiratory issues and other health problems caused by prolonged exposure to dust. - Compliance with Safety Standards:

Helps industries comply with workplace safety and environmental regulations related to air quality and dust control. - Increased Productivity:

A cleaner workspace leads to better efficiency and productivity by reducing interruptions caused by dust-related issues. - Easy Maintenance:

The modular design and easy-to-clean components simplify maintenance, saving time and resources.

Shot Blasting Machine Point of View

Sanding Suction Wall stands out as a cutting-edge solution for industrial dust collection needs. It combines efficiency, durability, and ease of use in a single system. Whether you’re a small workshop or a large-scale industrial unit, this system ensures that your workspace remains clean, safe, and compliant with regulatory standards.

Invest in the Sanding Suction Wall today to experience the difference in air quality and workplace safety. Your team deserves a healthier and more productive environment, and this system delivers exactly that.