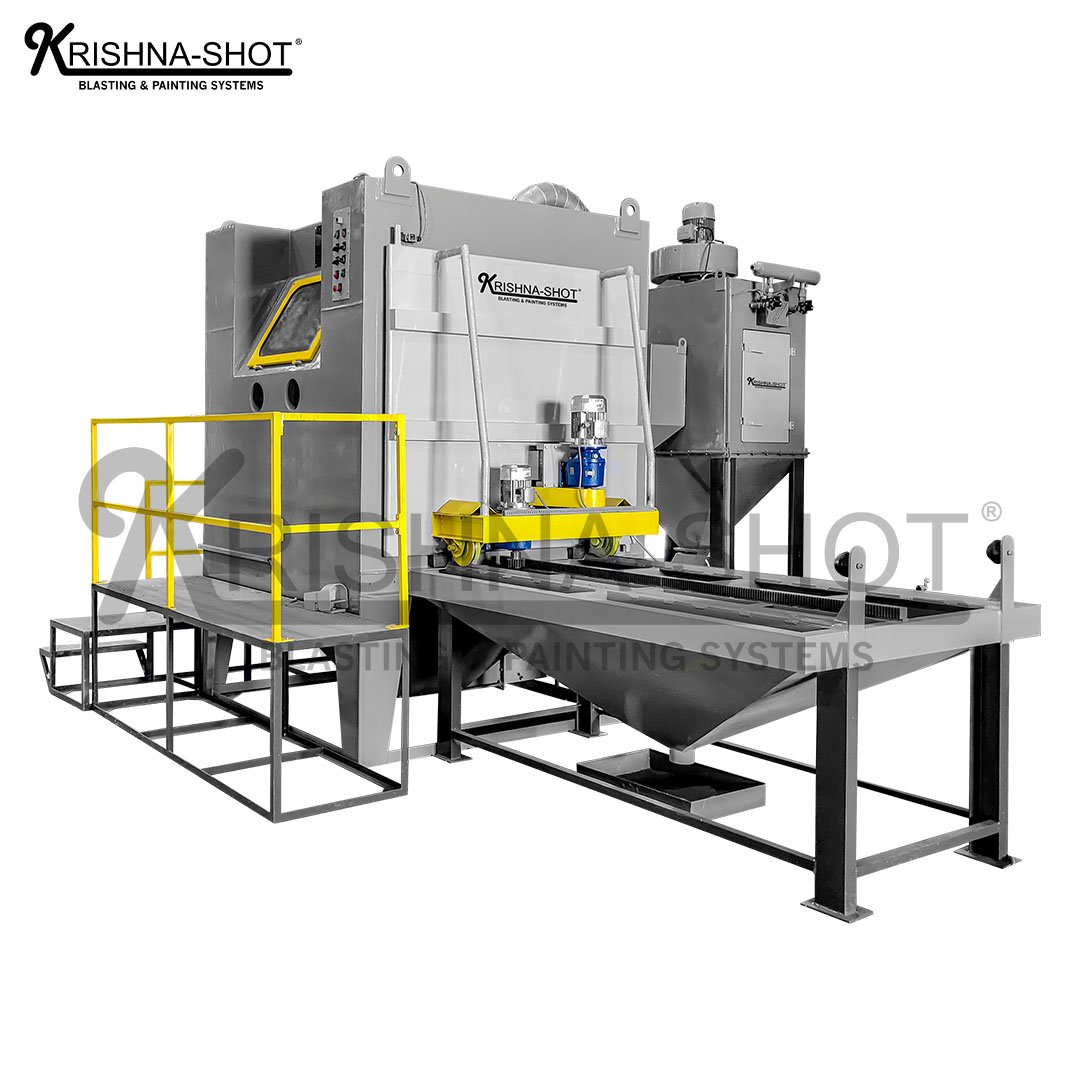

Satellite Shot Blasting Machine

Manufacturer & Supplier Details

- Brand Name: KRISHNA-SHOT®

- Company Name: Krishna Shot Blasting India Pvt. Ltd.

- Experience: 20+ Years in Surface Finishing Solutions

- Verification: Trustseal Verified (Leading Manufacturer & Supplier)

- Delivery Time: Typically 30 Days

- Address: Plot No. 30, Sarita Vihar Nagar, Near Tanawada, Main Salawas Rd, Jodhpur, Rajasthan 342005

- Specialization: Shot Blasting Machines, Blast Rooms, and Paint Booth Systems

- Customer Support: Dedicated after-sales service and technical support

- Certifications: ISO-certified products

Description

Satellite Table Shot Blasting Machine: Precision Surface Cleaning and Finishing

The Satellite Table Shot Blasting Machine is a specialized and efficient tool designed for cleaning, surface preparation, and finishing of intricate and delicate components. Its innovative design combines the functionality of multiple rotating satellite tables with high-performance shot blasting capabilities, making it ideal for industries like automotive, aerospace, and general manufacturing. This machine excels in treating small to medium-sized parts that require precision, uniformity, and high-quality surface finishes.

What is a Satellite Table Shot Blasting Machine?

A Satellite Table Shot Blasting Machine uses a combination of rotating satellite tables and abrasive blasting technology to clean and prepare surfaces. The machine is equipped with multiple small rotating tables, or satellites, mounted on a larger central turntable. As the central table rotates, the satellite tables also spin, exposing all sides of the workpieces to the blasting process. Abrasive media, such as steel shots or grits, is propelled at high velocity to remove contaminants like rust, scale, paint, or old coatings and prepare the surface for further processing, such as painting, coating, or welding.

This design is especially suited for components with complex geometries, ensuring that even hard-to-reach areas are thoroughly cleaned and treated.

Key Features of a Satellite Table Shot Blasting Machine

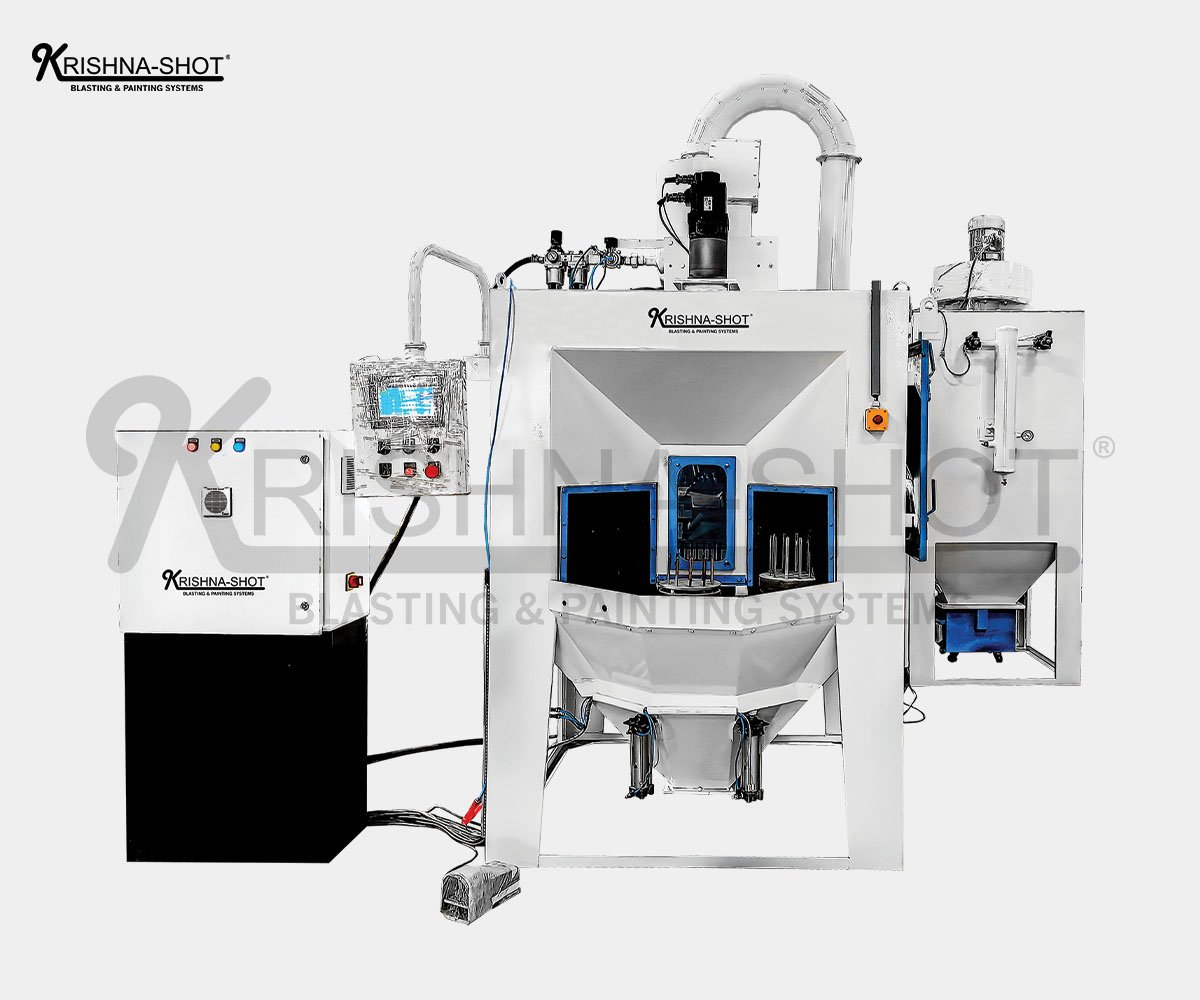

- Multiple Rotating Satellite Tables

The satellite tables rotate individually while mounted on a central turntable. This ensures complete and uniform exposure of all sides of the workpiece to the blasting process. The simultaneous rotation enhances precision and efficiency, making it suitable for parts with intricate designs. - High-Performance Turbines

The machine is equipped with powerful turbines that propel abrasive media at high speeds. These turbines are designed for durability and efficiency, ensuring consistent blasting results while minimizing wear and tear. - Compact and Space-Saving Design

Satellite table shot blasting machines are compact, making them ideal for facilities with limited space. Despite their small footprint, these machines offer high productivity and performance. - Customizable Configurations

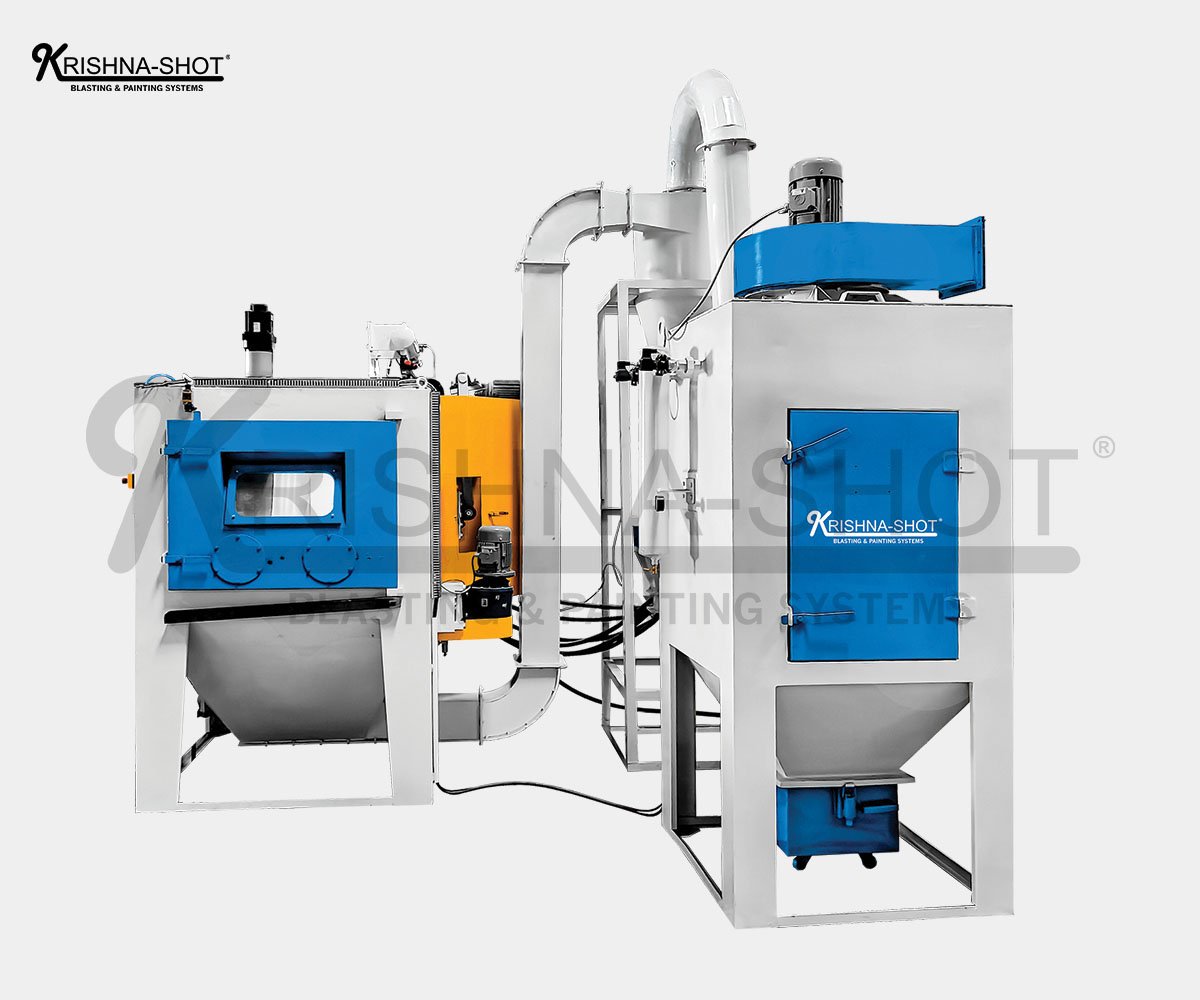

Many machines offer flexible configurations, such as adjustable table sizes and varying numbers of satellites, allowing customization based on specific production requirements. This ensures compatibility with a wide range of part sizes and shapes. - Advanced Dust Collection System

To maintain a clean and safe working environment, the machine is equipped with a dust collection system that captures airborne particles generated during the blasting process. This not only enhances workplace safety but also ensures compliance with environmental standards. - User-Friendly Controls

Satellite table shot blasting machines are designed with easy-to-use control panels, allowing operators to set and monitor parameters such as blasting intensity, cycle time, and table rotation speed. Automation features enhance productivity and reduce manual intervention.

How Does a Satellite Table Shot Blasting Machine Work?

- Loading the Workpieces

Components are placed on the rotating satellite tables. Each table is designed to hold one or more parts securely, depending on their size and shape. - Blasting Process

As the central turntable rotates, the satellite tables spin simultaneously, exposing all surfaces of the workpieces to the blasting stream. Abrasive media, propelled by high-speed turbines, removes rust, paint, and other contaminants. - Continuous Rotation for Uniform Results

The synchronized rotation of the satellite and central tables ensures that even the most complex geometries are treated uniformly. This minimizes the risk of uneven cleaning or surface preparation. - Media Recycling

The abrasive media is collected, separated from contaminants, and recycled for reuse in subsequent blasting cycles. This reduces operational costs and ensures consistent performance. - Unloading the Finished Parts

After the blasting cycle is complete, the workpieces are removed from the satellite tables. The treated surfaces are now clean, smooth, and ready for further processing.

Applications of Satellite Table Shot Blasting Machines

- Automotive Industry

The machine is extensively used for cleaning and preparing components like engine parts, gears, and brake discs. Its ability to handle intricate shapes and hard-to-reach areas makes it indispensable for automotive manufacturing and restoration. - Aerospace Industry

In aerospace, precision is paramount. Satellite table shot blasting machines are used to clean and prepare turbine blades, structural components, and other critical parts. The machine’s ability to deliver uniform results ensures that components meet strict quality standards. - Metalworking and Fabrication

The machine is ideal for removing scale, rust, and welding spatter from fabricated metal parts. It also prepares surfaces for painting, powder coating, or galvanizing, ensuring strong adhesion and a flawless finish. - Die Casting and Foundries

Satellite table shot blasting machines are used to clean castings by removing sand, scale, and other residues. Their precision makes them suitable for intricate castings with complex geometries. - Tool and Machinery Manufacturing

Tools and machinery parts often require cleaning and finishing to improve durability and performance. The satellite table shot blasting machine ensures that every part is treated thoroughly, enhancing its lifespan and functionality.

Advantages of Using a Satellite Table Shot Blasting Machine

- Precision Cleaning

The combination of rotating satellite tables and high-speed turbines ensures that every part is uniformly treated, even in hard-to-reach areas. This precision is critical for components with intricate shapes and delicate features. - Increased Productivity

The multi-table design allows multiple parts to be treated simultaneously, significantly improving throughput and reducing downtime. Automation features further enhance productivity. - Versatility

The machine can handle a wide variety of materials, including steel, aluminum, and cast iron, making it suitable for diverse applications across industries. - Cost-Effective Operation

The recycling of abrasive media and efficient energy consumption make the satellite table shot blasting machine a cost-effective solution for surface preparation. - Enhanced Surface Quality

The machine delivers consistent and high-quality surface finishes, ensuring that parts are ready for painting, coating, or other finishing processes. - Compact and Space-Efficient

Its compact design makes it ideal for facilities with limited space, while its high productivity ensures maximum output in a small footprint.

Safety and Maintenance Considerations

- Operator Safety: Always wear personal protective equipment (PPE), including safety goggles, gloves, and hearing protection. Ensure that the machine’s dust collection system is functioning properly to minimize exposure to airborne particles.

- Regular Maintenance: Inspect the machine regularly to ensure that components like turbines, hoses, and nozzles are in good condition. Replace worn parts promptly to maintain performance.

- Proper Training: Operators should be trained in the safe handling and operation of the machine, as well as in adjusting settings for different tasks.

Shot Blasting Machine Point of View

The Satellite Table Shot Blasting Machine is a versatile and efficient tool for precision surface cleaning and finishing. Its unique design, featuring multiple rotating satellite tables, ensures uniform treatment of intricate components, making it indispensable for industries that demand high-quality surface preparation. With its compact size, high productivity, and advanced features, this machine is an excellent choice for manufacturers looking to enhance their cleaning and finishing processes while maintaining cost efficiency. Whether you’re working in automotive, aerospace, or metal fabrication, the satellite table shot blasting machine delivers reliable and superior results.