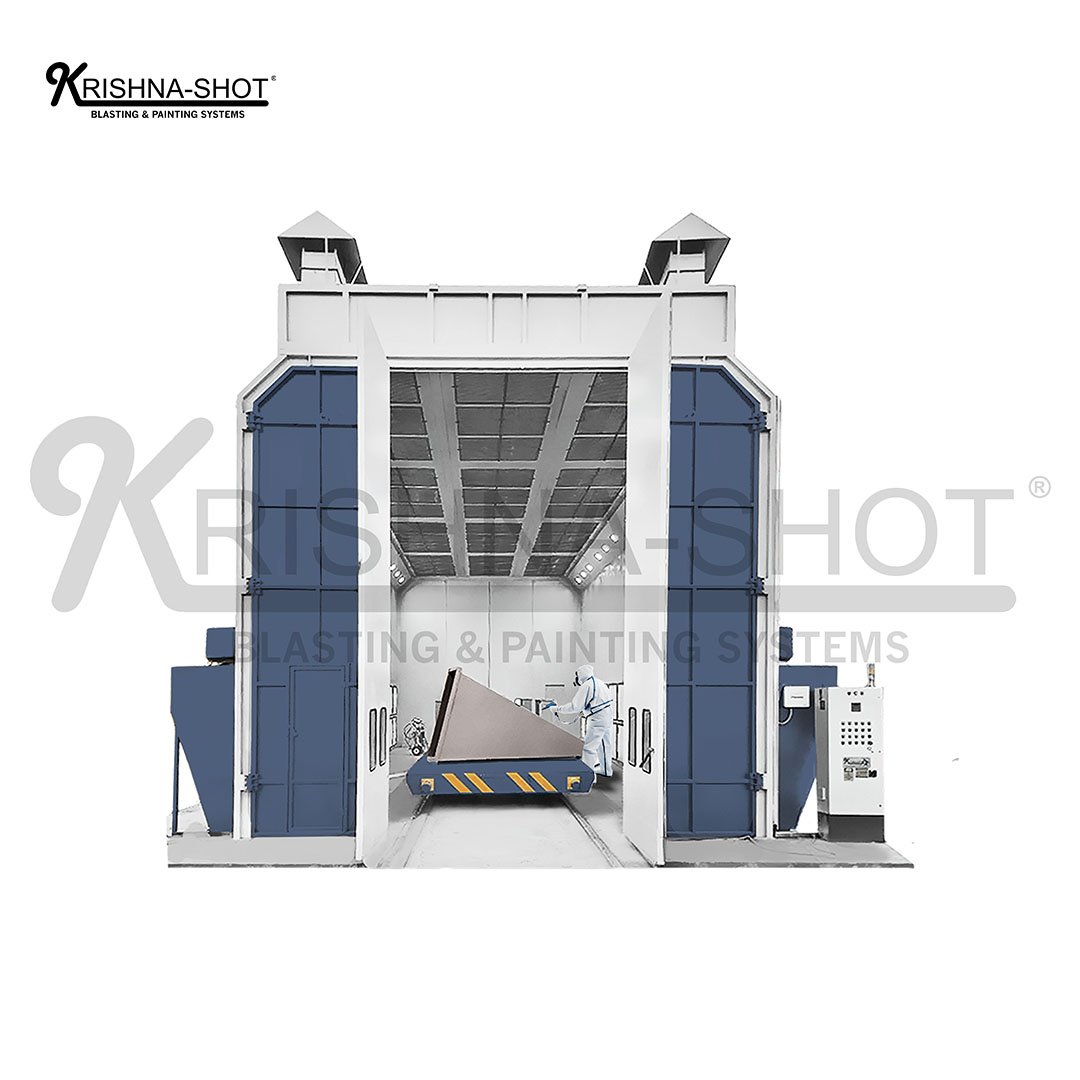

Side Draft Paint Booth

Manufacturer & Supplier Details

- Brand Name: KRISHNA-SHOT®

- Company Name: Krishna Shot Blasting India Pvt. Ltd.

- Experience: 20+ Years in Surface Finishing Solutions

- Verification: Trustseal Verified (Leading Manufacturer & Supplier)

- Delivery Time: Typically 30 Days

- Address: Plot No. 30, Sarita Vihar Nagar, Near Tanawada, Main Salawas Rd, Jodhpur, Rajasthan 342005

- Specialization: Shot Blasting Machines, Blast Rooms, and Paint Booth Systems

- Customer Support: Dedicated after-sales service and technical support

- Certifications: ISO-certified products

Description

Side Draft Paint Booth

Advanced Painting Solution for Precision and Cleanliness

A Side Draft Paint Booth is an essential industrial equipment used in various sectors, including automotive, manufacturing, aerospace, and furniture industries, to apply coatings or paints to products while ensuring a clean and controlled environment. This type of paint booth utilizes a side-draft airflow system to draw paint overspray and fumes away from the workpiece, maintaining a safe and efficient painting process. Its design and functionality make it an ideal solution for achieving high-quality finishes and keeping the working environment free from harmful contaminants.

What is a Side Draft Paint Booth?

A Side Draft Paint Booth is a specialized ventilation system designed for applying paint or coatings to various objects. The main feature that distinguishes side draft booths from other types of paint booths is their side-draft airflow design, where air is drawn from the sides of the booth and exits through the exhaust filters or vents located at the rear or bottom of the booth. This helps to create a continuous airflow that moves any overspray, fumes, or particles away from the work area, reducing the risk of contamination and ensuring that only the paint reaches the surface of the workpiece.

This type of booth is used extensively in environments where high-quality finishes are necessary, and it also serves to protect workers from inhaling hazardous fumes and particles.

Key Features of the Side Draft Paint Booth

- Efficient Side-Draft Airflow Design The side-draft design is the key feature of this booth. It provides a horizontal flow of air that helps push the overspray towards the exhaust filters, ensuring that the painting process remains clean. This airflow direction minimizes the risk of overspray settling on nearby surfaces, thus improving the overall finish of the workpiece.

- Optimized Airflow for Contaminant Removal A consistent airflow in a side draft booth is crucial for removing harmful fumes, dust, and excess paint particles. The air intake is typically positioned on the sides of the booth, which helps in directing the flow of contaminated air away from the operator and the painted surface, ensuring a cleaner and safer work environment.

- Exhaust Filters for Cleaner Air Side draft paint booths come equipped with powerful exhaust filters at the rear or bottom of the booth. These filters capture and remove harmful particles, paint fumes, and overspray, ensuring that only clean air is released into the surrounding environment. The use of high-efficiency filters ensures that the air leaving the booth meets environmental standards and reduces the potential for contamination.

- Adjustable Air Velocity The booth features adjustable air velocity settings, allowing operators to control the speed at which air moves through the booth. This feature provides flexibility depending on the type of workpiece, the kind of paint or coating being used, and the level of cleanliness required for the job.

- Durable and Safe Construction Side Draft Paint Booths are built using high-quality materials such as stainless steel or other durable, corrosion-resistant materials to withstand long-term exposure to paints and chemicals. The construction is designed to be sturdy and able to handle the rigors of industrial environments while ensuring the safety of workers.

- Noise Reduction Technology Many side draft booths incorporate noise-reducing features to ensure a quieter work environment. The fans and motors used for air circulation are designed to operate efficiently with minimal noise, reducing the impact of sound pollution in the workplace.

How Does the Side Draft Paint Booth Work?

- Prepping the Workpiece Before painting, the workpiece (whether it’s a car, a piece of furniture, or any other object) is placed inside the side draft paint booth. The booth should be free of dust or contaminants to ensure a high-quality finish, so it is crucial that the surfaces are clean before the painting process begins.

- Activating the Airflow Once the workpiece is in position, the side-draft ventilation system is activated. Air is drawn into the booth from the sides and moves horizontally across the booth. This airflow is controlled and ensures that overspray and any particles generated by the paint are captured and directed toward the exhaust filters.

- Spraying the Paint The operator uses a spray gun to apply paint to the workpiece. As the paint is applied, any overspray is carried by the side draft airflow and directed towards the exhaust filters. The controlled air pressure ensures that the paint is distributed evenly, leading to a smooth and uniform finish on the workpiece.

- Exhausting Contaminants After the paint overspray is captured by the airflow, it moves toward the exhaust system, which includes filters that remove particles and fumes. This ensures that no contaminants remain in the booth, protecting both the operator and the quality of the painted surface. The clean air is expelled from the booth, and harmful contaminants are contained.

- Finishing the Process Once the painting is complete, the booth continues to exhaust any remaining fumes and overspray to ensure that the air inside the booth is clean. Depending on the type of workpiece and paint, drying or curing times may vary, and the booth will often have provisions for drying or curing the painted surface.

Benefits of Using a Side Draft Paint Booth

- Improved Paint Finish The side-draft airflow ensures that the paint is applied smoothly and evenly, minimizing the risk of dust, overspray, and contaminants settling on the surface of the workpiece. This results in a more professional, high-quality finish that is free from imperfections.

- Safer Working Conditions By removing harmful fumes and particles from the air, the side draft paint booth provides a safer working environment for operators. The exhaust system ensures that no hazardous materials are inhaled, which is essential for maintaining worker health in industries that frequently work with volatile chemicals and paints.

- Better Environmental Compliance The side draft paint booth’s exhaust system is designed to meet environmental regulations by ensuring that the overspray and fumes are captured and filtered out before being released into the atmosphere. This helps businesses comply with local emissions standards and reduce their environmental impact.

- Cost-Effective and Efficient The side-draft design helps reduce waste by efficiently containing overspray and paint fumes. The media recycling system and high-efficiency filters ensure that the booth operates cost-effectively. Additionally, the precise airflow control leads to less paint wastage and a more efficient painting process, saving both time and materials.

- Versatility for Various Industries Side draft paint booths are versatile and can be used in a variety of industries, including automotive, aerospace, furniture, and manufacturing. They can be adapted to suit different sizes and types of workpieces, from small parts to large vehicles, providing flexibility for a range of applications.

- Low Maintenance With advanced filtration systems and durable construction, side-draft paint booths are designed to be low-maintenance. The filtering system ensures that paint overspray and fumes are removed, which reduces the need for frequent cleaning and upkeep. Additionally, the airflow controls and air quality are monitored, ensuring the system operates at peak efficiency.

Applications of Side Draft Paint Booths

- Automotive Painting Side draft paint booths are widely used in the automotive industry for painting vehicles, parts, and accessories. The uniform airflow ensures a flawless paint job on cars and trucks, providing an even finish while protecting workers from paint fumes.

- Furniture and Woodworking In the furniture industry, side draft booths help achieve smooth and durable finishes for wooden pieces. Whether it’s for cabinets, tables, or other furniture, side draft paint booths help achieve a polished look while maintaining safety standards.

- Aerospace and Aviation The aerospace industry requires the painting of delicate parts and components, often under tight quality control standards. Side draft paint booths ensure that parts are painted without imperfections and are free from contaminants that could affect their function.

- General Manufacturing Manufacturers of various products, such as machinery, electronics, and metal parts, use side draft booths for coating and painting. The controlled environment reduces the risk of contamination and ensures parts are finished to the highest standards.

Shot Blasting Machine Point of View

The Side Draft Paint Booth is a specialized painting solution that ensures precision, cleanliness, and safety in the painting process. With its side-draft airflow design, it offers a controlled environment where overspray, fumes, and dust are efficiently removed, resulting in a high-quality finish and a safer workspace. Whether used in automotive painting, furniture manufacturing, or aerospace applications, this type of booth provides an effective, cost-efficient, and environmentally-friendly solution for a wide range of industries. By improving the overall quality of the painted surface and ensuring compliance with environmental regulations, the side-draft paint booth is a crucial tool for any business involved in industrial painting.