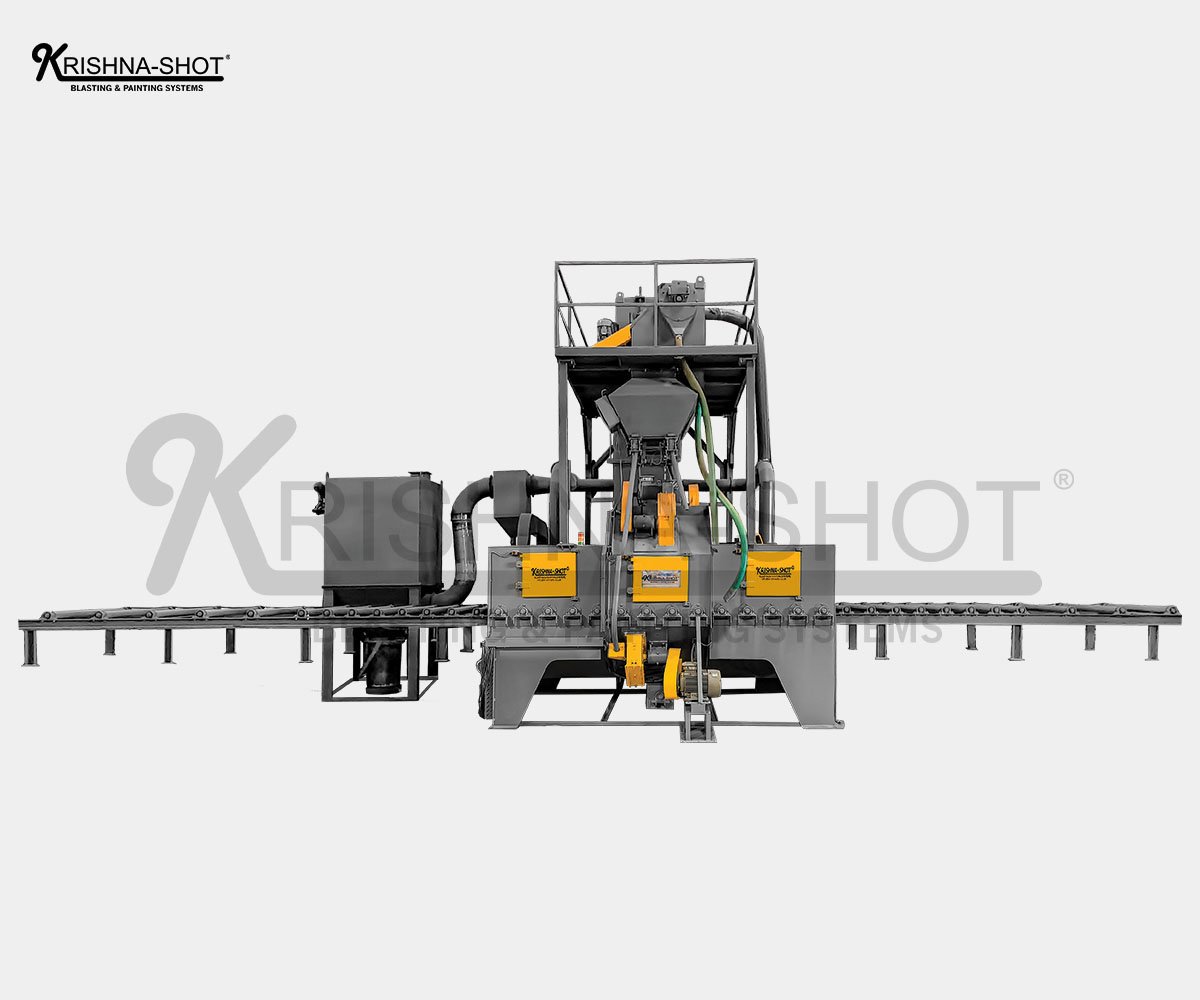

Stone Shot Blasting Machine

Manufacturer & Supplier Details

- Brand Name: KRISHNA-SHOT®

- Company Name: Krishna Shot Blasting India Pvt. Ltd.

- Experience: 20+ Years in Surface Finishing Solutions

- Verification: Trustseal Verified (Leading Manufacturer & Supplier)

- Delivery Time: Typically 30 Days

- Address: Plot No. 30, Sarita Vihar Nagar, Near Tanawada, Main Salawas Rd, Jodhpur, Rajasthan 342005

- Specialization: Shot Blasting Machines, Blast Rooms, and Paint Booth Systems

- Customer Support: Dedicated after-sales service and technical support

- Certifications: ISO-certified products (if applicable)

Description

Stone Shot Blasting refers to a process where abrasive materials (shot media) are propelled at high speed onto the surface of marble or stone to clean, texture, or finish it. This technique is used for a variety of purposes, including surface cleaning, enhancing texture, and creating specific finishes on stone products, particularly marble, granite, and other natural stones.

Key Aspects of Stone Marble Shot Blasting:

- Abrasive Media:

- The most common types of abrasive media used in shot blasting of stone and marble are steel shot, grit, aluminum oxide, or sometimes even sand.

- The choice of media depends on the desired surface effect—whether it’s a smooth finish, matte, or rough texture.

- Abrasive media is selected based on its ability to effectively clean, etch, or texture the stone surface without damaging the material.

- Shot Blasting Process:

- Shot Blasting involves the use of centrifugal force to launch abrasive media at high speed onto the stone surface.

- This process removes dirt, stains, or old coatings from the stone while also giving it a textured finish. The shot blasting process can be fine-tuned for varying levels of aggression to achieve the right finish on the marble.

- Applications:

- Surface Cleaning: Shot blasting is highly effective for cleaning marble surfaces by removing embedded dirt, dust, grime, and old coatings like paint or varnish.

- Texturing: The process creates a rough or matte surface on marble, which can be desirable for aesthetic purposes or for creating non-slip surfaces.

- Etching: In some cases, shot blasting can be used to create etchings or decorative patterns on the stone’s surface, adding a unique visual appeal.

- Deburring: In marble processing, shot blasting can help remove any sharp edges, leftover debris, or imperfections after cutting or shaping the stone.

- Advantages:

- Effective Cleaning: Shot blasting provides a powerful and efficient way to clean marble and stone surfaces, especially in large-scale operations.

- Consistent Finish: The controlled nature of the shot blasting process ensures a uniform texture or finish across the entire surface.

- Cost-Effective: Since the abrasive media can be recycled, the process is relatively economical over time.

- Surface Preparation: It enhances the stone’s surface by preparing it for subsequent treatments, such as sealing, polishing, or coating.

- Types of Stone Finishes Achieved by Shot Blasting:

- Matte Finish: Shot blasting can create a subtle, non-reflective matte surface, commonly used for flooring or architectural purposes.

- Rough Finish: For creating a more pronounced textured surface, typically for non-slip applications, such as for outdoor stone pavers or stairs.

- Honed Finish: A slightly polished yet non-reflective finish, achieved by fine-tuning the abrasive media used in the shot blasting process.

- Equipment Used:

- Shot Blasting Machines: These can be either manual or automated, depending on the scale of production. They typically feature blast wheels or turbines that propel the abrasive media onto the stone.

- Dust Collection Systems: Shot blasting can create significant dust, so dust collection is necessary to maintain a clean working environment and prevent environmental contamination.

- Abrasive Recovery Systems: Recycled shot media is collected, cleaned, and reused in the process to reduce waste and operating costs.

- Safety Considerations:

- Shot blasting can produce high-speed flying particles and dust, so proper safety equipment is essential, including protective gear such as goggles, gloves, masks, and ear protection.

- Ventilation systems must be in place to minimize exposure to airborne dust and ensure worker safety.

Applications in Industry:

- Architectural Stone: Shot blasting is often used to treat marble used in building facades, flooring, countertops, and other architectural elements.

- Stone Processing: Stone manufacturers use shot blasting to prepare marble and granite slabs before cutting or polishing.

- Outdoor Landscaping: Shot-blasted marble can be used for paving stones, tiles, and steps where a textured, non-slip surface is necessary.

Advantages of Stone Marble Shot Blasting:

- Enhanced Aesthetic Appeal: Provides unique finishes and textures that enhance the appearance of the marble, giving it a distinctive, artistic look.

- Increased Durability: By cleaning the stone and creating a rougher surface, shot blasting can help enhance the durability and resistance to wear.

- Improved Adhesion: For marble used in coatings or painting, shot blasting helps improve the adhesion of paints, sealers, or other surface treatments.