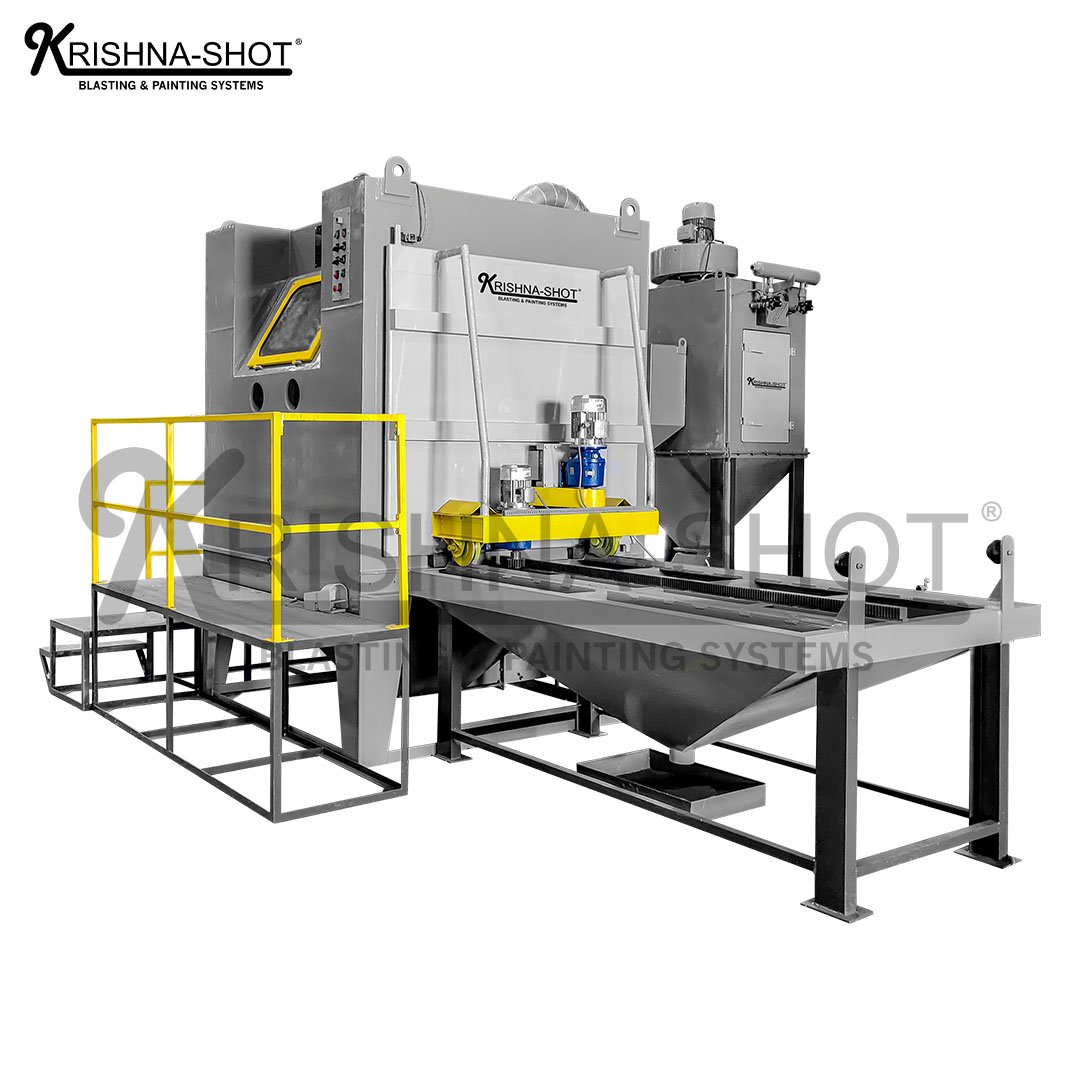

Tyre Mould Suction Blasting Machine

Manufacturer & Supplier Details

- Brand Name: KRISHNA-SHOT®

- Company Name: Krishna Shot Blasting India Pvt. Ltd.

- Experience: 20+ Years in Surface Finishing Solutions

- Verification: Trustseal Verified (Leading Manufacturer & Supplier)

- Delivery Time: Typically 30 Days

- Address: Plot No. 30, Sarita Vihar Nagar, Near Tanawada, Main Salawas Rd, Jodhpur, Rajasthan 342005

- Specialization: Shot Blasting Machines, Blast Rooms, and Paint Booth Systems

- Customer Support: Dedicated after-sales service and technical support

- Certifications: ISO-certified products

Description

Tyre Mould Suction Blasting Machine

Tyre Mould Suction Blasting Machine uses an abrasive media propelled by suction or vacuum technology to clean the surfaces of tyre moulds. These moulds, which are used to shape the rubber compounds into tyres, often accumulate excess rubber, dust, and other particles that can impair their performance and the quality of the tyres produced. The suction blasting process efficiently removes these contaminants without damaging the moulds, ensuring they remain in optimal condition for high-quality tyre production.

In this type of blasting system, the abrasive media (such as steel shot, sand, or aluminum oxide) is drawn into the blasting chamber via suction, where it is directed at the mould surface. The machine’s controlled blasting process removes any rubber deposits, contaminants, or residues from the mould cavity.

Key Features of a Tyre Mould Suction Blasting Machine

- Suction Blasting Technology

Unlike traditional pressure-fed sandblasting systems, a suction blasting machine uses vacuum or suction to draw abrasive material into the blasting stream. This method offers more control over the media flow and reduces the risk of over-blasting or damaging delicate surfaces. - Customizable Abrasive Media

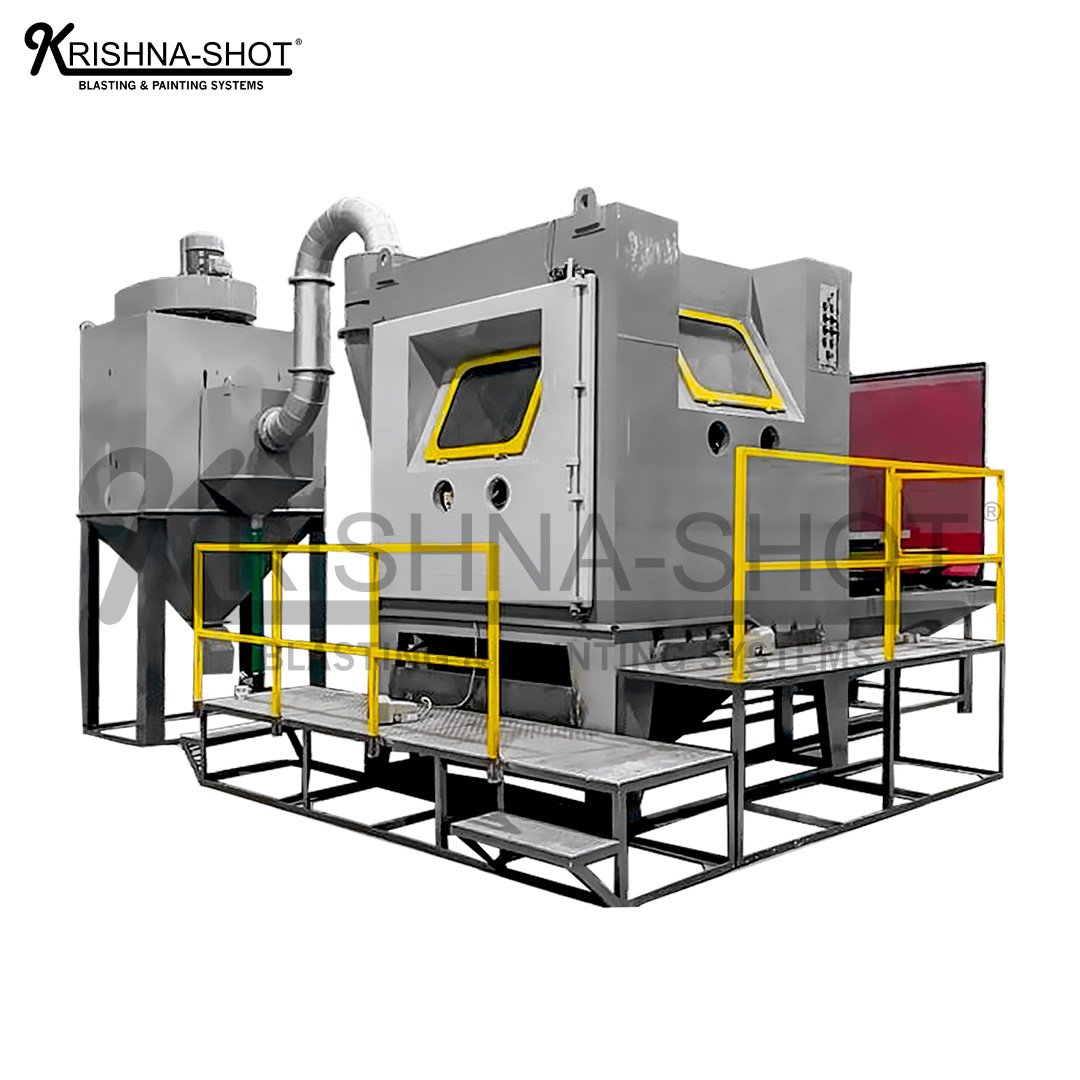

The machine can work with a variety of abrasive materials, such as steel shot, glass beads, sand, or other media suited for specific cleaning applications. This flexibility allows operators to choose the best abrasive for the type of contamination or surface they are cleaning. - Efficient Dust Collection

Tyre mould suction blasting machines are equipped with integrated dust collection systems that ensure the workspace remains clean and safe. The dust collection system traps airborne particles generated during the blasting process, preventing contamination and promoting a healthier work environment. - High Precision and Uniform Cleaning

The suction blasting process provides consistent, uniform cleaning without the need for excessive pressure. This makes it ideal for cleaning tyre moulds, as it ensures that all cavities and details of the mould surface are cleaned thoroughly and evenly. - Automated Controls

Many tyre mould suction blasting machines come with programmable controls that allow operators to adjust parameters such as blasting time, media flow, and suction power. This automation helps optimize performance and ensures repeatable and reliable results. - Durable Construction

Tyre mould suction blasting machines are designed for heavy-duty industrial use. They are built with durable materials that withstand the rigors of continuous operation and the harsh nature of abrasive media. These machines are designed for long-lasting performance and minimal maintenance.

How Does a Tyre Mould Suction Blasting Machine Work?

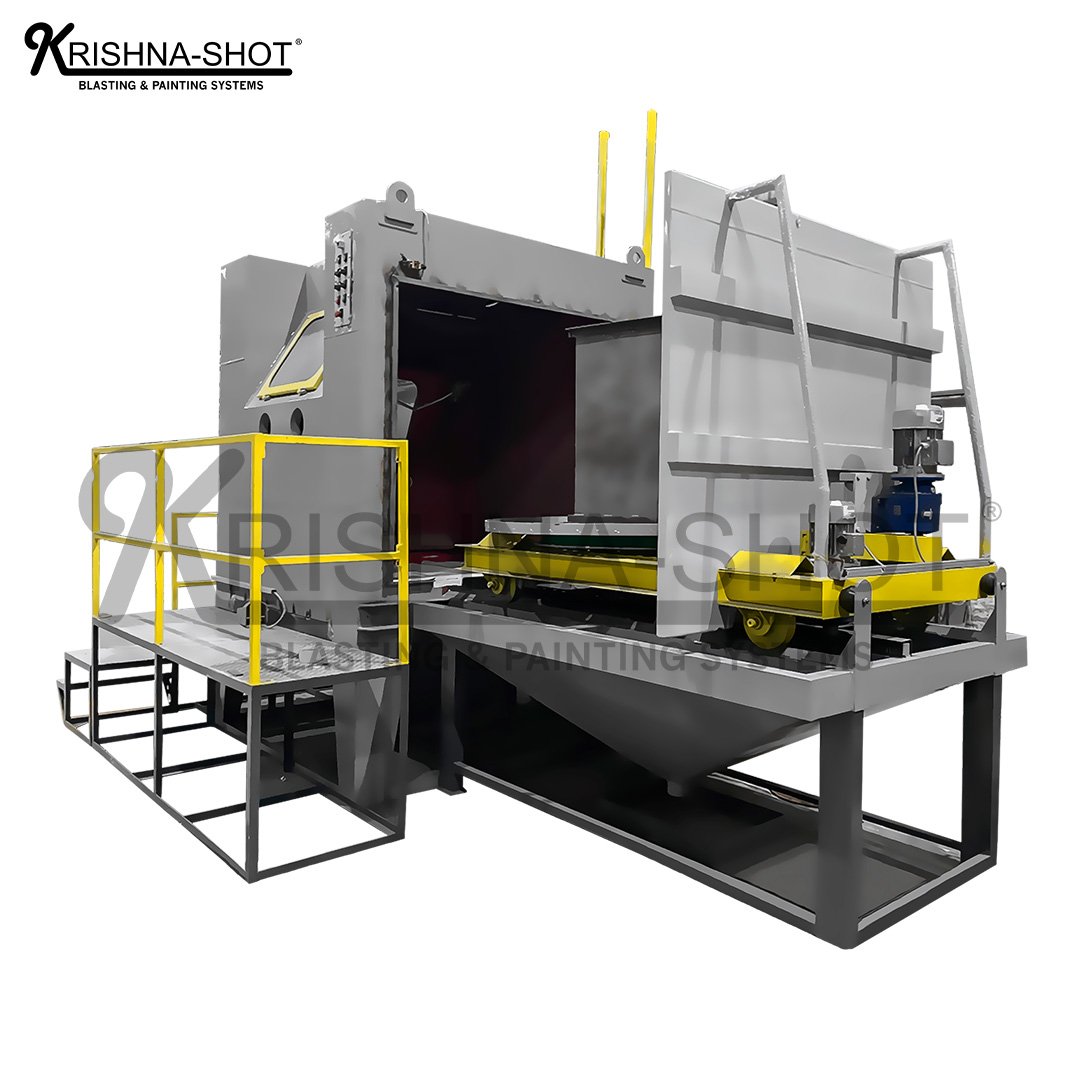

- Loading the Tyre Moulds

The tyre moulds are loaded onto a conveyor or platform within the machine’s chamber. The machine is designed to accommodate moulds of various sizes, ensuring compatibility with different tyre production setups. - Blasting Process

Once the moulds are positioned, the suction system draws abrasive media into the chamber. The abrasive media is propelled at high velocity onto the mould surface using suction pressure. This cleans and removes any residual rubber, dirt, or contaminants from the surface of the mould. - Vacuum Recovery of Abrasive Media

The suction system not only helps in blasting the media but also recovers the spent abrasive for reuse. This closed-loop system ensures efficient use of materials and reduces waste, making the process more cost-effective. - Dust Collection

As the abrasive media impacts the mould surface, fine dust and particles are generated. The machine’s dust collection system captures these particles, preventing them from contaminating the work environment and ensuring a safer operation. - Unloading the Cleaned Moulds

After the blasting cycle is complete, the cleaned tyre moulds are unloaded, ready to be reused for further production. The moulds are now free of any rubber buildup or other contaminants, ensuring high-quality tyre production.

Applications of Tyre Mould Suction Blasting Machines

- Tyre Manufacturing

The primary application of a Tyre Mould Suction Blasting Machine is in tyre production. The machine ensures that tyre moulds are free of rubber residues, contaminants, or any other buildup that could affect the quality and consistency of the tyres produced. This process is vital for maintaining moulds and ensuring optimal performance. - Rubber Mould Cleaning

Apart from tyres, these machines are used in the cleaning of other rubber moulds used in various industries. Whether it’s for seals, gaskets, or custom rubber components, the suction blasting process ensures thorough cleaning without damaging the moulds. - Maintenance of Injection Moulds

Suction blasting is also ideal for cleaning and maintaining injection moulds used in manufacturing other rubber products. By removing contaminants from the surface of the mould, the machine improves the quality and accuracy of injection-molded parts. - Preventative Maintenance

The machine is often used for routine maintenance of tyre moulds and other rubber moulds. Regular cleaning ensures the moulds remain free from contaminants and prolongs their service life, reducing the need for costly repairs or replacements.

Advantages of Tyre Mould Suction Blasting Machines

- Precision Cleaning Without Damage

The suction blasting process provides precise cleaning without causing any damage to the delicate mould surfaces. This is especially important for tyre moulds, where fine details and accuracy are essential for consistent tyre production. - Cost-Efficiency

The closed-loop abrasive recycling system reduces the cost of media usage by allowing for reuse. This results in lower operating costs and less waste, making the machine an economical choice for continuous production environments. - Enhanced Quality Control

Tyre mould suction blasting ensures that each mould is cleaned to the highest standard, which directly impacts the quality of the tyres produced. Clean moulds allow for better rubber moulding, reducing defects and ensuring uniformity across all produced tyres. - Increased Productivity

The efficient suction blasting process cleans multiple moulds quickly, helping improve throughput and reduce downtime in tyre manufacturing. Automation features help reduce manual intervention, making the operation smoother and more efficient. - Improved Safety

The dust collection system ensures that harmful dust particles generated during the blasting process are effectively captured and removed from the working environment, improving safety for operators and meeting workplace air quality standards.

Maintenance and Safety Considerations

- Regular Inspection

Regular inspection of the suction blasting machine ensures optimal performance. Operators should check components such as the suction system, blasting nozzles, and dust collection system for wear and tear. - Proper PPE

Operators should wear protective gear, including goggles, gloves, and respiratory protection, to safeguard against exposure to abrasive media and dust particles during operation. - Dust Collection System Maintenance

Ensure that the dust collection system is regularly cleaned and maintained to prevent clogging and ensure continuous operation without environmental hazards. - Media Replenishment

Regularly monitor the condition and amount of abrasive media in the system. Replenish or replace the media as necessary to maintain optimal blasting performance.

Shot Blasting Machine Point of view :

Tyre Mould Suction Blasting Machine plays a vital role in maintaining clean and high-quality tyre moulds, ensuring the production of tyres with consistent quality and reduced defects. Its precision, efficiency, and ability to handle complex mould geometries make it indispensable in the tyre manufacturing industry. With its automated features, dust collection system, and cost-effective abrasive recycling, the tyre mould suction blasting machine helps improve productivity, reduce downtime, and extend the life of costly moulds. Whether for routine maintenance or the production of high-quality tyres, this machine is an essential tool in modern manufacturing facilities.